2025

MAKE OFFER Tarus #TPTCGD512S CNC Gun Drilling Machine

Follow these steps (see pic in last photo for details). Tarus #TPTCGD512S CNC Gun Drilling Machine.

Comments Off

Follow these steps (see pic in last photo for details). Tarus #TPTCGD512S CNC Gun Drilling Machine.

Comments Off

It is in good working order. We also sell mills, lathes, grinders, and saws etc. Let me know if you’re looking for anything else. Check out my other listings as well. Thank you for looking.

Comments Off

USED TABLE ONLY IF YOU NEED OTHER PARTS WE CAN DISCOUNT. NEEDS CLEANING IN EXCELLENT SHAPE.

Comments Off

Well Index 700 2HP Vertical Knee Milling Machine 230/460V 3PH No Powerfeed. Please reference this SKU number when making inquiries. Tested and works as it should. 48″ x 9″ Overall Table. Does not have any motors for powerfeed axis. Has almost zero play on all the axis Very tight controls. BULLSEYE INDUSTRIAL SALES, LLC. Bullseye Industrial Sales is proud to be a dedicated supplier to the manufacturing industry. We are a leading source for quality new and used equipment. We understand that keeping your equipment running is vital keeping your customers happy and we can provide equipment or replacement parts to get your machine or next project back on schedule. We get hundreds of items in daily, if we don’t have it today check back tomorrow. Next Day & Second Day Air Services are available. We choose the carrier. Will there be a dock or forklift. Please make sure that we have the BOL. Prefer to pick it up yourself? You are welcome to do so, by appointment. We will load it free of charge unless otherwise stated in the listing. After the return period has ended, you can no longer return the product. Unless otherwise specifically agreed to in writing by. All goods are so “AS IS’ and “WITH ALL FAULTS meaning, without limitation, that. Which extend beyond the description of the goods on the face hereof; and.

Comments Off

THE GOOSENECK SECTION IS ABOUT 36 APPROX. THERE ARE MEASUREMENTS IN THE PICTURES. CHECK OUT MY OTHER LISTINGS. NO WARRANTIES GIVEN OR IMPLIED. International Buyers – Please Note. I do not mark merchandise values below value or mark items as “gifts” – US and International government regulations prohibit such behavior.

Comments Off

For sale is an unusual Sheldon milling machine attachment as shown. It shows signs of its age but appears to be in good condition and the spindle and drive shaft spin smoothly with no play in the gears. If there are additional tests or measurements that would be helpful just ask. Check out my other listings for more tooling.

Comments Off

As shown in pictures. The bar in the last picture is 3 3/4″L x 3/8″W.

Comments Off

Right Angle Curved Plate Machining Fixed Plate 90 Degree Right Angle Machine. Otherwise we can’t guarantee the package would arrive smoothly. Return accepted in 30 days after you receive the item. Return package must be in the original packaging, item must be in new condition.

Comments Off

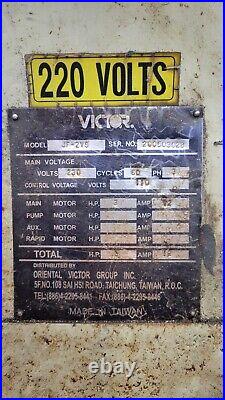

Model JF-2VS, Serial # 200503028, 220V 3 phase power required. This is a running mill removed from production to add a bigger mill. Riser block has been added for extra height. This part can be easily removed if not wanted. Comes equipped with a DRO and rapid travel. Uses R8 collets same as Bridgeport. She could use a deep cleaning but I do not want to invest the time in order to keep the sell price as low as possible. Currently inside shop in Pineville NC. Overhead bridge crane for easy loading on trailer.

Comments Off