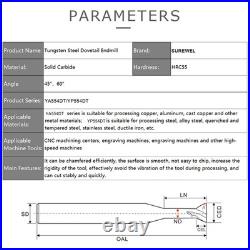

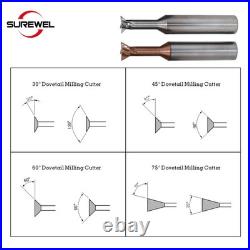

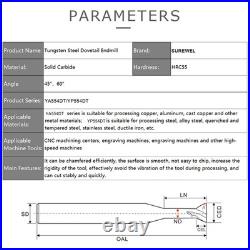

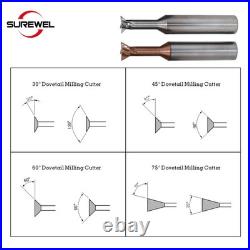

Carbide Dovetail Milling Cutter CNC Tool 30 45 60 Degree Machining Tool for Metal End Mill 1mm-16mm. Geometric angle: 30°, 45°, 60°, 75° Versatile with 4 geometric angles, this cutter caters to diverse milling needs. Applicable Ranges: Suitable materials and mechanical equipment, Designed for a wide range of materials and machinery, this cutter is a versatile tool. Material: Carbide, Crafted from robust carbide, this cutter ensures long-lasting performance and precision. Design and Style: Long shank, The long shank design provides stability and control for intricate dovetail cuts. Coating: AlTiSiN, Featuring a AlTiSiN coating, the cutter offers superior wear resistance and smooth operation. Precision Engineering for Metalworking. The SUREWEL Carbide Dovetail Milling Cutter is a testament to precision engineering, designed to deliver unparalleled performance in metalworking. Crafted from high-grade carbide, this tool is engineered to withstand the rigors of high-speed machining, ensuring longevity and reliability. The TiAIN coating not only enhances the tool’s durability but also provides superior wear resistance, making it an ideal choice for demanding applications. The SUREWEL Carbide Dovetail Milling Cutter is not just about precision. It’s also about efficiency. The optimized design facilitates efficient chip removal, reducing the time required for post-processing. This tool is perfect for those who value both quality and speed in their machining operations. Whether you’re working on a small project or a large-scale production, this dovetail milling cutter is designed to deliver consistent, high-quality results every time.