2026

R8 Splined Spindle Assembly 545mm Milling Machine Part for Lathe Maintenance

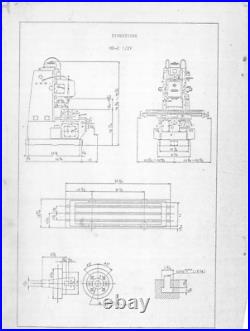

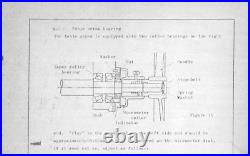

545mm Milling Machine R8 Spindle + Bearings Assembly. After the spindle is replaced, the old machine, such as the new machine effect, changes due to the long-term wear of the spindle, the bearing clearance is large, and the tool jumps, resulting in the surface and side of the milling workpiece is not smooth, rough and uneven. Name: Milling R8 spindle+bearings. Length:545mm(Suitable for most milling machines). Packing quantity: 1set(R8 spindle+bearings). You can make order with no worry. Any concern just feel free to let us know, we’ll reply in 24 hours in normal condition. Orders are processed from Monday-Friday. Not on the weekends & public holidays. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.

Comments Off