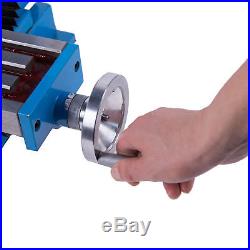

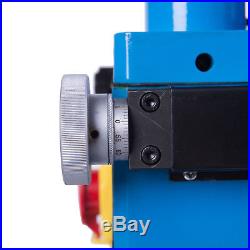

The Bridgeport XY CNC retrofit kit includes the mechanical components needed to convert the X and Y axes of your manual Bridgeport, Jet, Enco or similar J-head type mill for CNC operation. All components are precision engineered. The kit includes (2) Size 42 motor mounting plates, (2) motor pulleys, (2) screw pulleys, (2) motor covers, (2) drive belts, and all needed bolts, dowels, and spacers. For use with any NEMA 42 standard size motors. Made in the USA. Motors and controller are not included. CNC Bridgeport Knee Conversion Kit. The Bridgeport Knee CNC retrofit kit includes the mechanical components needed to automate the knee of a manual Bridgeport, Jet, Enco or most any similar type milling machine for motorized control. Kit includes a size NEMA 42 motor mounting plate, motor pulleys, lead screw pulley, motor cover, drive belt, and all required bolts, dowels, and spacers. For use with NEMA 42 size motors. The Bridgeport CNC Quill retrofit kit includes the mechanical components needed to convert the Z axis of your manual Bridgeport or Enco mill for CNC operation. All components are precision engineered and include the quill feed drive frame w/ size 34 motor mount, the ball screw and ball nut assembly, the motor and ball screw pulleys, the motor cover, and all needed bolts, dowels, and spacers. Ideally suited for use with the 34HT1275 motor (Order separately). High Performance Ballscrew Kit. Upgrade your Bridgeport series 1 style knee mill with this precision-rolled ballscrew kit. The screw and nut assemblies are made of hardened steel for durability and long life. This ballscrew kit will provide a load life expectancy of 50 million inches of travel at an operating load of 400 pounds. The many advantages in this design over other products on the market include. Accuracy of +/. 003 per foot. Preloaded Ball Nuts- Each ball nut is preloaded to eliminate lost motion. This system stiffness provides faster response from a control command. This added stiffness also allows heavier cuts and climb milling thus increasing productivity. The preload is adjustable. This feature permits readjustment for wear and reduces the need for repair or future replacement. Brush-Type Wipers: Brush-type wipers, at the ends of each preloaded ball nut assembly, prevent entry of dirt and metal chips. Easy-Access Lubrication: Lubrication of ball nuts made easy through 5/32 holes in the flanges. These holes provide for attachment of existing lube tubing. Available lengths for the X axis are: 36″, 42″, and 48 (these refer to the table lengths). The Y axis selections are: 9″, 12″, and 16. He Y axis length to select is the travel distance and not the table width. Bridgeport Ballscrew Kit 9 x 36. Bridgeport Ballscrew Kit 9 x 42. Bridgeport Ballscrew Kit 9 x 48. Bridgeport Ballscrew Kit 12 x 36. Bridgeport Ballscrew Kit 12 x 42. Bridgeport Ballscrew Kit 12 x 48. Bridgeport Ballscrew Kit 16 x 36. Bridgeport Ballscrew Kit 16 x 42. Bridgeport Ballscrew Kit 16 x 48. Variable Spindle Speed Kit, 2 and 3 HP. The Variable Spindle Speed kit includes the cabinet that mounts to the mill, a 2 or 3 HP VFD, emergency stop, variable speed control and electronic display as well as the necessary mounting hardware. 2HP Variable Speed Spindle Controller, LeGrande. 3 HP Variable Speed Spindle Controller, LeGrande. CNC Rack-Mount Control Systems for Full-Size Machines. A complete pre-engineered package to automate your full-size Bridgeport, Enco, or similar size knee mill. Just couple the motor shafts to your machine’s drive screws, plug in the cables, turn on the power, and install the software. You can immediately jog the motors by pressing Ctrl-J, and clicking on the X+, X-, Y+, Y-, Z+, and Z- buttons! It’s literally that easy! You can write simple part programs as well as use the built in wizards screens to generate programs for pockets and bolt hole circles. The drill holes can be simple down/up or with chip break cycles, chip clearing cycles etc… You can also use your favorite CAM program to generate complex 3D simultaneous surfacing machining tool paths. This same controller can also be used to automate a lathe. You would just use the TurnMaster Pro software. The 3 Axis version would also be able to control a tool turret. A tower orientation is available on request. DriveRack high performance power driver. Choice of motors Choose between. The 2 axis models are typically for lathes and come standard with (1) 34HT1275 and (1) 34HT750 motors. The 3 axis models are for Mills and come standard with (2) 42HT1700 and (1) 34HT1275 motors. All motors come with prewired armoured cables and locking circular connectors. G-code control & graphical software. All cables & illustrated manuals. 2 axis Rack Mount System- MN400. 3 axis Rack Mount System – MN400. 4 axis Rack Mount System – MN400. 2 axis Rack Mount Microstepping System- MN400. 3 axis Rack Mount Microstepping System- MN400. 4 axis Rack Mount Microstepping System- MN400. Engineering Quality CNC Components and Systems Since 1985. The item “Milling Machine CNC motor mount Kit, A Retrofit for Bridgeport Knee Mills” is in sale since Tuesday, May 23, 2017. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “microkineticscnc” and is located in Kennesaw, Georgia. This item can be shipped worldwide.

- Brand: MicroKinetics

- MPN: 999-1000-100

- Model: BPT XY Retrofit Kit

- Country/Region of Manufacture: United States