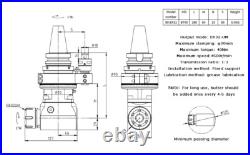

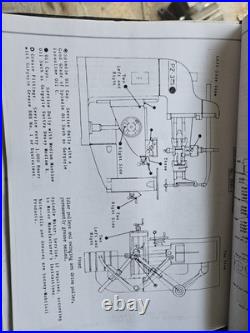

Small Ceramic Grinding Machine Ceramic Ball Mill 220V. The pot mill ball mill, also known as the rolling jar machine, is a precision grinding and mixing device for laboratories and small-scale production. The machine is beautiful and novel, and has a compact structure, convenient operation, high working efficiency and uniform fine grinding particle size. It is the preferred choice for scientific research, teaching, experimentation and production. It is widely used in the industries of biomedicine, ceramic glaze slurry, metal powder, non-metallic minerals, new materials and so on. 23.634.622.6 inches (608857.5cm). Rev of the Rollers. About 59kg (130.1LBS). Used for ball grinding of glaze or other raw materials, and used for dry or wet grinding. More suitable for dry grinding. L ceramic milling jar1 (including a cover and ball milling beads). Read the operating instructions carefully before use. Always keep children away from the machine, PROHIBIT children from operating the machine. Never touch the RUNNNING Parts or insert hardware into the machine. Do not put hands into the machine during operation. Always unplug the machine when assembling or disassembling the unit. Protective devices must not be made unserviceably or be removed. Grinding jars may be very hot after grinding. Wet grinding may cause high pressure in the grinding jar–Danger of squirting! When oxidable materials, such as metals, organic materials, wood, coal and plastic, are ground or sieved, the risk of spontaneous ignition (dust explosion) exists whenever the fine particles exceed a specific percentage. While these materials are being ground, it is necessary to take special safety precautions e. Wet grinding and the work must be supervised by a specialist. The instrument is not explosion-proof and is unsuitable to grind or sieve materials which are explosive or combustible or promote combustion. Do not allow the instrument to run in an unsupervised state. Due to the vibrations, under certain operating conditions, the machine may creep along the surface on which it is located or mounted. The wear-resistant rubber rollers are used so that the service life of the machine can be prolonged. The rubber rollers are not prone to hardening and aging after long-term use, have good resilience performance and can adapt to different working environments. The 220V 550W high-quality motor adopts metal gears and is durable, motor transmission adopts variable-speed transmission of a belt and a pulley, and the equipment noise is low. The driving force is stable and consistent to ensure smooth operation. The control switch is simple in structure and easy and convenient to operate, well achieving stable starting, greatly reducing the mechanical shock stress, prolonging the service life, reducing the vibration of the whole machine and effectively protecting the machine. Machine is equipped with a 10L ceramic jar, the triangular buckle sealing design is adopted in the tank opening. The ball milling tank is suitable for dry grinding and wet grinding according to different raw materials. Machine is equipped with alumina ceramic milling balls with different sizes. The milling balls have high adaptability and practicability and can be selected as required. The milling efficiency and quality can be greatly improved. High-quality bearings are adopted to ensure smooth running of the rollers, and can be freely adjusted to adapt to different ball milling jars. Bearing wheel lubricating oil needs to be regularly added in the using process according to the frequency of use. Put the materials and grinding balls into the grinding jar. Cover the jar with the lid. Place the jar in the center of the machine. Turn on the switch and start grinding. Item Number (134183): 1 x Ceramic Ball Mill 220V. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.