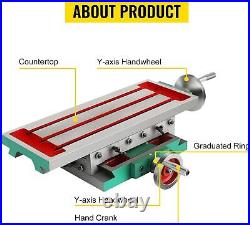

3/4/5 Axis CNC 6040 USB Port 1500W Router Milling Engraving CNC Cutting Machine. 4 AXIS 1500W USB PORT. This CNC 6040T machine is suitable for industry, Technology Research, Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes. It can work with various materials(metallic & non-metallic), such as: wood, pmma or other plastic, MDF board, native wood, PVC, Acrylic, wood, composite board plywood. And soft metal, like aluminum, copper and silver to engrave them into 3D/2D works etc. It can used for engraving: advertising signs, PCB, nameplates, badges, seals, bronzing plate, aluminum alloy, acrylic plates, ABS resin double color plate, PVC foaming board, indentation plates, signs, construction models. Instrument panels, wooden products, etc. The mini CNC router Frame is movable. The machine can connect with computer as other external device such as printer, scanner.. With the assist of the CNC ROUTER 6040T, your design idea will be real-time display. CNC engraving machine parameters. X, Y, Z Working Area: 600(Y)390. Lathe structure: 6061/6063 Aluminium alloy. Y axis—1605 Ball Screws. Z axis—1204 Ball Screws. X axis—High intensity Chromeplate shaft. Y axis—High intensity Chromeplate shaft. Z axis—High intensity Chromeplate shaft. The spindle motor must connect with the VFD. It cannot directly connect with the supply voltage (AC 220V). Please don’t change the data setting of the VFD if you are not professional technicians, or it might damage the spindle motor. Material: 304 stainless steel, Copper coil, Pressure cast aluminum pipe water jacket. VOLTS, current, power: AC 220V, 50Hz, 5A. 1.5 KW VFD. Spindle speed: 24000 rpm. Max working frequency: 400Hz. Principal axis collet: ER11collet, Standard configuration :6mm. Speed mode: By adjusting the VFD output voltage and operating frequency from 0-24000RPM. Lubrication way: lubricated by high grease. Repeat accuracy: 0.05mm. Spindle precision: radial beat acuities 0.03mm. Carving Instructions: G code / TAB files / nc file / NCC files. Communication interface: through USB connection with computer. Support system: windows XP / win7 32bits system. Carving speed: 0-2500mm/min(different materials differ). Operating Voltage: AC 220V. Control unit: Toroidal transformer + PWM power supply module + TB6560 stepping motor drive. Command code: G code. Protection: Emergency stop button. 1.5KW water-cooled VFD. Is available operating for long time, which can reinforced the processing ability of the machine and can be used to process aluminum alloy and hard wood. Water cooling spindle works more stable and durable. High quality accurate ball Screws drive make the engraving more precision. Anti-blackflash, high precision, long life circle. Assembling and locating the CNC machine on steady desk well. Make sure that your computer has a USB port output. Place the control box in a ventilated dry place where there is no dust, no moisture. Connecting the control box with the CNC machine and you computer and make sure the plug will not come off. Correctly connect the machine with the controller. Don’t suspended the cable which connect the Spindle motor with axis(X, Y, Z, A). It will damage the driver of the controller. Correctly install the Spindle motor and the heat pump. The heat pump should be covered completely in the water, then turned on the electric current to check whether the water-cooling system working well. Before turn on the machine, please check all the cable and water- cooling system to make sure they are working fine. You can enjoy making you dream with using our CNC machine now. 4 AXIS 1500W USB PORT+RC. Notes:Please prepare a computer with USB Interface. 1X main unit (Frame). 1X main unit (working base). 1X Sinal cable for A axis. 1X 25pin Parallel lines. 10X 47mm round head. 6X 410mm black Inner six angle screw with nut. 8X 520mm black Inner six angle screw. 4X 58mm Flat Philip’s head screw with nut and gasket. 8X 624mm BALCK FLAT Inner six angle screw. 2X six angle Wrench(3mm). 2X six angle Wrench(4mm). Suitable for PCB, wood, Plexiglass, PVC, Crystal Acrylic, RESIN, Plastic, SEALS, MDF, COMPOSITE, Aluminum material, Copper, Iron. It can work with various materials(metallic & non-metallic), such as: wood, pmma or other. Plastic, MDF board, native wood, PVC, Acrylic, wood, composite. Like aluminum, copper and silver to engrave them into. It can used for engraving: advertising signs, PCB, nameplates, badges, seals, bronzing plate, aluminum alloy, acrylic plates, ABS resin double color plate, PVC foaming board, indentation plates, signs, construction models, instrument panels, wooden products, etc. The machine can connect with computer as other. External device such as printer, scanner.. CNC Engraving Machine Parameters. X, Y, Z Working Area : 600(Y)390. Lathe structure : 6061/6063 Aluminum alloy. Y axis :1605 Ball Screws. Z axis:1204 Ball Screws. High intensity Chromeplate shaft. 1, The spindle motor must connect with the VFD. 2, It cannot directly connect with the supply voltage (AC110V). 3, Please don’t change the data setting of the VFD if you are not professional technicians, or it might damage the spindle motor. Pressure cast aluminum pipe water jacket. 5A, 1.5KW VFD. Spindle speed : 24000 rpm. Max working frequency : 400Hz. Principal axis collet: ER11collet. Speed mode:By adjusting the VFD output voltage and operating frequency. Repeat accuracy:0.05mm. Spindle precision:radial beat acuities 0.03mm. Communication interface:through USB connection with computer. Maximum Idle speed:1500mm/min. Working Speed :50-1500mm / min (different material with different speed settings). Control unit:Toroidal transformer + PWM power supply module + TB6560 stepping motor drive. Computer connection:USB port. Command code:G code. Protection:Emergency stop button. 1, The NEW 1.5KW water-cooled VFD is available operating for long time, which can reinforced the processing abil. Ty of the machine and can be used to. Process aluminum alloy and hard wood. 2, water cooling spindle works more stable and durable. 3, High quality accurate ball Screws drive make the engrving more precision. Make sure that your computer has a 25pin parallel port output. L box in a ventilated dry place where there is no dust, no moisture. Damage the driver of the controller. L the Spindle motor and the heat pump. The heat pump should be covered completely in the water, then turned on the electric current to. Check whether the water-cooling system working well. Waterproof design, very durable, anti-dirt, oil spray. Power by USB port. Dimensions: 22 x 8 x 3cm. The usb self-check light, you can type the ” scroll” on the keyboard to activate it. Directional motion control: X+, X-, Y+, Y-, Z+, Z-, A+, A. Feed rate control: F+, F. Jog rate: J+, J. Spindle speed: speed up, slow down. Programming: E-stop, cycle start, spindle on/off, Redo, single step, original point. 3 AXIS 1500W USB PORT. Suitable for PCB, wood, Plexi glass, PVC, Crystal Acrylic, RESIN, Plastic, SEALS, MDF, COMPOSITE, Aluminum material, Copper. This CNC 6040 machine is suitable for industry, Technology Research, Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes. Like aluminum, copper and silver to engrave them into 3D/2D works etc. It can used for engraving: advertising signs, PCB, nameplates, badges, seals, bronzing plate, aluminum alloy, acrylic plates, ABS resin doublecolor plate, PVC foaming board, indentation plates, signs, construction models, instrument panels, wooden products, etc. Cnc engraving machine parameters. It cannot directly connect with the supply voltage (AC220V). VOLTS, current, power: AC110 /60Hz, 5A, 1.5KW VFD. Max working frequency: 60Hz. Support system: Windows XP/Win7. Computer connection: USB port. The NEW 1.5KW water-cooled VFD is available operating for long time, which can reinforced the processing abilty of the machine and can be used toprocess aluminum alloy and hard wood. High quality accurate ball Screws drive make the engrving more precision. Otherwise, It will damage the driver of the controller. The Spindle motor and the heat pump. Before turn on the machine, please check all the cable and water-cooling system to make sure they are working fine. (3 AXIS 1500W USB PORT+RC). Mode: By adjusting the VFD output voltage and operating frequency from 0-24000RPM. Is available operating for long time, which can reinforced the processing abil. High quality accurate ball Screws drive make the engr. Flash, high precision, long life circle. (3 AXIS 1500W Parallel Port). Notes:Please prepare a computer with DB25 parallel Interface. This machine needs to connect to a computer through its controller box with a. Parallel cable (both included). It is not recommended to connect to a notebook through a. Parallel port as the power saving features tend to interrupt the data flow. It is also not recommended to connect to a computers with 64 bit versions of Windows due to problems with the Parallel port driver. Suitable for PCB, wood, Plexiglass, PVC, Crystal Acrylic, RESIN, Plastic, SEALS, MDF, COMPOSITE, Aluminum material, Copper. Lathe structure:6061/6063 Aluminium alloy. Y axis:1204 Ball Screws. X axis:High intensity Chromeplate shaft. Y axis:High intensity Chromeplate shaft. Z axis:High intensity Chromeplate shaft. Material:304 stainless steel. Spindle speed:24000 rpm. Max working frequency:400Hz. Principal axis collet:ER11collet. Mode:By adjusting the VFD output voltage and operating frequency from 0-24000RPM. Lubrication way:lubricated by high grease. Carving Instructions:G code / TAB files / nc file / NCC files. Communication interface:through parallel connection with computer. Support system:windows XP / win7. Toroidal transformer + PWM power supply module + TB6560 stepping motor drive. 3, High quality accurate ball Screws drive make the engr. Connecting the control box with the CNC machine and you computer. And make sure the plug will not come off. (3 AXIS 1500W Parallel Port+RC). Notes: Please prepare a computer with DB25 parallel Interface. PCB, wood, Plexiglass, PVC, Crystal Acrylic, RESIN, Plastic, SEALS, MDF, COMPOSITE, Aluminum material, Copper. This 6040T machine is suitable for industry, Technology Research, Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes. The mini router Frame is movable. With the assist of the ROUTER 6040T, your design idea will be real-time display. Y axis–1605 Ball Screws. Z axis–1204 Ball Screws. X axis–High intensity Chromeplate shaft. Y axis–High intensity Chromeplate shaft. Z axis–High intensity Chromeplate shaft. It cannot directly connect with the supply voltage (AC110V). VOLTS, current, power: AC110 /60Hz, 5A. Principal axis collet: ER11collet, Standard configuration: 6mm. Communication interface: through parallel connection with computer. Environment: Windows XP / Win7, 32bits system. Computer connection: Parallel port. 1.5 KW water-cooled VFD. Ty of the machine and can be used to process aluminum alloy and hard wood. Compatability: fit for Type3/ArtCAMParameter. Assembling and locating the machine on steady desk well. Connecting the control box with the machine and you computer and make sure the plug will not come off. Installing a control Drive on your computer. Llowing our manual or guideline to set. You can enjoy making you dream with using our machine now. (5 AXIS 1500W USB Port). Make sure that your computer has a 25pin USB port output. Don’t suspended the cable which connect the Spindle motor with axis(X, Y, Z, A, B). Highlights of water cooling system. It can cool the spindle and protect the machine. Avoid the spindle burn out. Can engrave the high hardness or metal. It can improve the efficiency and accuracy of the machine. 2X Sinal cable for A B axis. This 6040T machine is suitable for industry, Technology Research. Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes. With the assist of the ROUTER 6040, your design idea will be real-time display. X, Y, Z Working Area:600(Y)390. Y axis:1605 Ball Screws. Material:304 stainless steel, Copper coil, Pressure cast aluminum pipe water jacket. Speed mode:By adjusting the VFD output voltage and operating frequency:from 0-24000RPM. Software environment:32-bit version of Windows 2000, Windows XP, Windows Vista, or Windows 7 (64-bit versions will not work). Non-integrated Video Card with 32MB RAM(Large G-code files, especially 3D files will require a video card with 512MB RAM or higher). 50-1500mm/min(different material with different speed settings). Anti-black flash, high precision, long life circle. Note:We only sell machine without software. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. Easy installation, Convenient Use, Easy Operation. Drilling, Milling, Engraving, Cutting, Carving. Do not send to Brazil. Transportation does not include. Creative Design, Durable Material, Beautiful Appearance.