2024

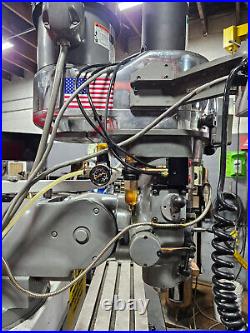

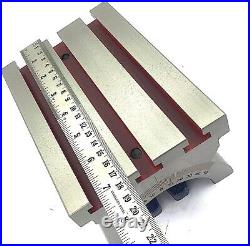

Bridgeport J and 2J Head Pattern Milling Machine Attachment Uses 1/4 Tool Bits

Bridgeport J and 2J Head Pattern Milling Machine Attachment. Accepts 1/4 Bars and Bits. 3/4 Shank / Arbor. Overall Length: 8 approximate. Brass Tagged: MACOMB PATTERN AND MFG. Used, bearings feel good, well maintained. Adapter slides over the spindle housing until the gears mesh well.

Comments Off