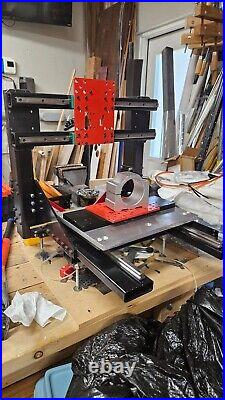

6 / 160 mm Dividing Head for Milling Machine. MT3 Headstock Taper & Complete Set & Simple Operation. Semi-Universal Dividing Head is a simple Index Center and can be used for direct and indirect dividing. Complete the gear, face, flute processing, and no need accessories, the same construction as universal type. With rotary indexer, the 24 quick-dividing holes can complete BS-2A 2,3,4,6,8,12,24 division indexing. Attache 3 dividing plates and the dividing head indirect dividing in any division indexing 2-50.51-380. Rich Dividing Head Set. Tough Equipment & Tools, Pay Less. VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Vertical & horizontal milling machine with headstock chuck for the lathe. Swing: 6-1/2″ / 168 mm, Center Height: 5″ / 128 mm. Our universal dividing head features ruggedly constructed hardened and ground worm gear. The reduction ratio is 1:40. Designed with a rotary table and indexing chuck for convenient operation, the 24 quick-dividing holes can complete 2, 3, 4, 6, 8, 12, 24 division indexing. The ball-bearing of this indexing head is of high precision and smooth turning. An extra dead center is provided for rapid use. Our rotary indexer comes with 3 dividing plates of different sizes. The tool has easy indexing of divisions from 2 to 50, with most numbers up to 380. The rotary indexer is ideal for various uses in milling, grinding, and drilling work. Chuck Diameter: 6 / 16 cm. Spindle Speed: 2500 RPM. Swing: 6-1/2 / 16.8 cm. Center Height: 5 / 12.8 cm. Reduction Ratio: 1:40. Net Weight: 77 lbs / 35 kg. Headstock Dimensions: 4.4″ x 7.9″ x 11.8 / 11.3 x 30.2 x 21.9 cm. Tailstock Dimensions: 4.5″ x 6.6″ x 5.2 / 11.5 x 17 x 13.4 cm. 1 x 6 Dividing Head. 2 x Dividing Plates. 3 x 6 Chuck Jaws. 1 x Dead Center. 1 x Set of Related Accessories. Adjustable Angle: The semi-universal dividing head features a 6 3-jaw chuck, Spindle Speed: 2500 RPM. The headstock is adjustable from the horizontal position to 90 degrees upward. Free 3 more jaws for 6 chuck. Solid Construction: This indexing head is made of HT 200 to be a long life. A rigid frame provides high accuracy with little backlash for a smooth rotation. Precise & Accurate: Dividing head milling machine with laser engraving scales. The 24 quick-dividing holes can complete 2, 3, 4, 6, 8, 12, 24 division indexing. One circle for 360 degrees, one scale stands for 1 degree. MT3 Tailstock Adjustable: Huge live center for heavy-duty workpieces. Ball-bearing precision; turns smoothly. The model of the tailstock is MT3. One extra dead center is included. Rich Dividing Head Set: 3 dividing head index plates are attached along with the dividing head for indirect dividing in any division indexing 2-50, 51-380 except prime numbers and specific other numbers. People Who Bought This Item Also Bought. VEVOR BS-0 Semi 5 Indexing Dividing Head 3-Jaw Chuck Tailstock For CNC Milling. VEVOR Compound Milling Machine Work Table 2 Axis Cross Slide Bench Drill Vise. VEVOR 8 Precision Horizontal and Vertical Rotary Table. Tilting Table 5 x 7inch for Milling Machines Swivel Angle Plate Adjustable Plate. VEVOR Tilting Milling Table Tilting Angle Milling Machine Adjustable Plate. VEVOR Rotary Table XY Axis Rotary Table 8 3-Slot for Milling Drilling. VEVOR 6 Rotary Table Horizontal Vertical Dividing Plates for Milling Machine. VEVOR Square Air Cooled Spindle Motor 2.2KW CNC Spindle Motor 220V ER20 Collet. VEVOR Milling Drilling Machine Worktable Cross Slide Table 4″ X 7.3″ Bench Table. VEVOR 2.2KW Air Cooled Spindle Motor for CNC Router Milling Engraving 4 Bearings. We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders. Please be aware that. Please DO NOT fill in the PO Box address. California Warehouse: City of Industry, CA. New York State Warehouse: Perth Amboy, NJ. Georgia Warehouse: Austell, GA. North Carolina Warehouse: Grove NC. Oregon Warehouse: AIRPORT WAY Portland, OR. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return. All emails will be responded to within. Special circumstances will be listed clearly in the listing. Please do check everything carefully after you received the parcel, any the damage except DOA (Dead-On-Arrival) would not be covered if it’s your fault. 4 / 100 mm. 6 / 160 mm. 0.28 / 7 mm. 0.83 / 21 mm. 6.5 / 168 mm. CA & TX & NJ & GA & NC &OR WAREHOUSE. All emails will be responded to within 12-24 hours.