2026

Haas CNC 93-4576 Red Grease 1 Gallon Mobilith Synthetic Grease 93-1933A Lube NEW

Haas CNC 93-4576 Red Grease 1 Gallon Mobilith Synthetic Grease 93-1933A Lube NEW.

Comments Off

Haas CNC 93-4576 Red Grease 1 Gallon Mobilith Synthetic Grease 93-1933A Lube NEW.

Comments Off

Removed from a functioning 1996 Haas HL-1 Lathe. Everything functioned on box except for the load meter.

Comments Off

Haas 93-32-5304B INDUCTOR, 4TH AXIS ASSEMBLY. Pulled from my 2004 HAAS VF3SS that i have deciede to part out.

Comments Off

Haas VF-3 Tool Carousel Geneva Index Plate Assembly – OEM – 1993 Machine. Pulled from a 1993 Haas VF-3 during teardown. This is the original Geneva indexing wheel / tool carousel drive plate. If you know, you know – this is the part that keeps the tool drum rotating correctly and NOT playing roulette with your tool numbers. This came off a running machine. Old school Haas steel – the kind that got heat-treated in an era when America still smoked Marlboros in the lunchroom. OEM Haas VF-Series carousel index plate. Correct slotted Geneva style indexing tabs. Heavy-wall center hub + bearing. Smooth rotation / no binding. Removed from a functioning tool changer. For 90′s VF-series carousel systems. Compatible with early VF-1 / VF-2 / VF-3 era tool chains that used this wheel style. Used – shop patina, industrial honest. Slots clean, no burrs or cracks. Ready to bolt in and run. NOT a “fresh off plasma table” bootleg part – this is OEM iron from the days Haas didn’t cut corners. Packed like it’s going across the country (or through UPS rugby team tryouts).

Comments Off

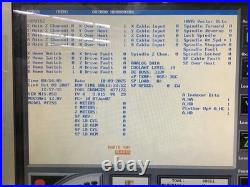

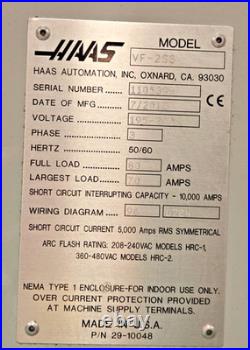

2007 HAAS CNC Mill VF2SS. HAAS VF2SS SUPERSPEED VMC. COO RD ROTATYON & SCALING.

Comments Off

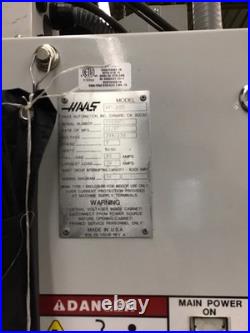

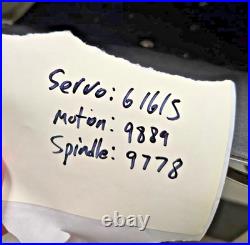

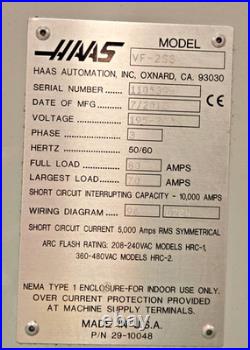

HAAS VF-2SS CNC Vertical Machining Center Mill Super-Speed Side Mount CAT40. Have two warehouses full of used equipment and tooling, and always getting new inventory.

Comments Off

&####127937; Haas OEM Bodine Gearmotor – Tool Changer / Carousel Drive. Pulled from a functioning Haas machine during a retrofit – not a mystery motor from someone’s uncle’s basement. This is the real Haas-spec Bodine 90V DC gearmotor, used on VF-series tool changers and auxiliary systems. If you’re chasing a ghost error on a Haas carousel, or your tool changer sounds like it’s screaming for help, this is probably what you’re looking for. Output Speed: 21 RPM. This thing is geared like it means business – 80:1 isn’t for spinning skateboard wheels, it’s for indexing steel and not complaining about it. Pulled from running machine. Spins smooth by hand. Industrial cosmetic wear – aka “it worked for a living”. Not tested post-pull because I don’t keep a full Haas strapped to my bench. Yet. &####128230; What You Get. OEM Haas Bodine motor. Will pack like NASA packed the lunar camera – foam, wrap, box, respect.

Comments Off

HAAS VF-2SS CNC Vertical Machining Center Mill Super-Speed Side Mount CAT40. Have two warehouses full of used equipment and tooling, and always getting new inventory.

Comments Off

HAAS VF-2SS CNC Vertical Machining Center Mill Super-Speed Side Mount CAT40. Have two warehouses full of used equipment and tooling, and always getting new inventory.

Comments Off

Condition: Used – Good Working Condition. This OEM Haas Tool Release Piston (TRP) was removed from a 1993 Haas VF-3 vertical machining center that was in full operational service. It has been cleaned, inspected, and shows standard cosmetic wear consistent with normal use. No cracks or leaks observed at time of removal. Function: Controls the pneumatic actuation of the drawbar for tool clamping/unclamping. Mounting: Bolt-on under spindle head with integrated pneumatic ports. Material: Anodized aluminum body with internal piston seals. Includes: Piston housing assembly only (no solenoid or air lines included). Condition: Clean threads and fittings; no stripped holes; smooth actuation. Genuine Haas OEM component (not an aftermarket clone). Restored from a running 1993 VF-3 machine. Compatible with umbrella and early side-mount tool changers. Leak-free and ready to install with new O-rings (recommended). Some external wear and light residue from normal shop use. Tested manually for free movement; not bench-tested under air. No visible structural damage. Designed for direct replacement or repair of early Haas VF-series vertical mills, including VF-1 through VF-4. Compatible with 40-taper spindle configurations.

Comments Off