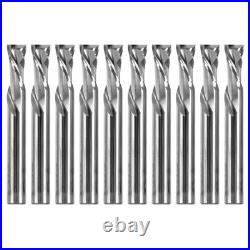

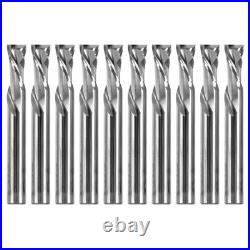

2 Flute Compression Cut Spiral End Mill CNC Router Bit (10 Pack) – 3/8 Shank – Yonico 33220-SC-10PK. Best for achieving a smooth finish on laminate or veneer finish applications. Cutting Diameter: 3/8″. Cutting Height: 7/8″. Shank Diameter: 3/8″. Overall Length: 3″. Flutes: 2 Compression bits cut down from the top of the stock and up from the botto. When working with any veneer finished material in your CNC machine, you need a compression spiral end mill to make full depth cut. These bits are designed to leave clean edges on the top and bottom faces of any material. The compression bit’s unique design pulls chips upward at the bottom of the stock and downward at the top face, producing chip-free surfaces that are perfect for cabinet and furniture parts. Compression cut spiral end mills are excellent for melamine, plywood, MDF and solid wood. That means that your order will be at your door in no time. Our 40,000+ reviews give you the assurance that our quality and service is right at the top.