2026

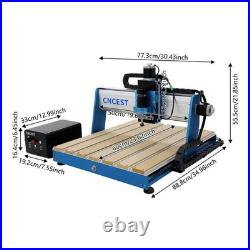

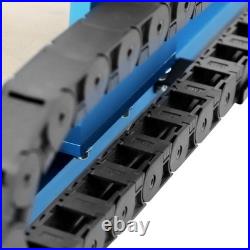

3 Axis CNC 6050 Milling Carving Engraver Router Machine Engraving Machine 500W

Cs-head{overflow:hidden;position:relative}. Title{margin:0;font-weight:400;font-size:14px;padding:5px 10px}. Dc-dock:hover{width:117px;background-position:bottom right}. Dc-cs{clear:both;max-width:100vw}. Dock-rb{right:0;bottom:0}. Title{font-weight: 700;font-size: inherit}. Title:after{content:’You may like’;color: #FFFFFF}. Cs-list>li:nth-child(n+16){display:none}. Title{margin:0;font-weight: 700;font-size: inherit}. Cs-list>li:nth-child(n+19){display:none}. Coupon{transform-origin:right top;right:0}. Cs-list{margin:0 0 0 -20px;padding:0;background:#FFF}. Cs-list:before{display:table;line-height:0;content:}. Cs-list:after{clear:both}. Cs-list>li{float:left;width:16.66%;list-style:none;box-sizing:border-box;padding:10px 0 10px 20px;position:relative;margin:0}. Cs-list-col6>li{width:16.66%}. Cs-list-col7>li{width:14.28%;padding-left:18px}. Cs-list-col8>li{width:12.5%;padding-left:16px}. Cs-list-col9>li{width:11.11%;padding-left:15px}. Cs-list-col10>li{width:10%;padding-left:14px}. Cs-list-col11>li{width:9.09%;padding-left:12px}. Cs-list-col12>li{width:8.33%;padding-left:10px}. Cs-list>liwidth:33.33%! Cover:after{display:block;content:”;padding-top:100%;background-repeat:no-repeat;background-size:cover;background-position:center}. Cs-list a{text-decoration:none}. Title{color:#333;margin:5px 0}. Title:after{display:block;display:-webkit-box;-webkit-line-clamp:2;-webkit-box-orient:vertical;font-size:14px;line-height:1.4em;height:2.8em;overflow:hidden;white-space:normal;word-break:break-word;-webkit-hyphens:auto;-ms-hyphens:auto;hyphens:auto}. Plus{height:20px;overflow:hidden}. Price:after{content:”;font-size:14px}. Origin{margin-left:3px;font-size:12px;color:#AAA}. Origin:after{display:none;content:”;text-decoration:line-through}. Coupon{display:none;width:60px;height:60px;border-radius:50%;background:rgba(224,13,12.8);color:#FFF;position:absolute;top:10px;right:10px;text-align:center;padding-top:12px;box-sizing:border-box}. Coupon:before{content:”;font-size:20px}. Coupon:after{content:’Off’;font-size:12px;position:absolute;bottom:8px;right:12px}. Title{min-height:12px}p:empty+hr{display:none}hr+span. Dc_tracker_img{display:none}#ds_div>. Dc_tracker_img:last-of-type{display:block} [data-lid="266081231700"]. Title:after{content:’1pc B177 + B178 MILL Milling Machine Part 25mm Clock Spring + Steel Housing US’}[data-lid="266081231700"]. Title:after{content:’Servo Power Feed Mill Machine Part – Bevel Brass Gear-Grinding Straight Teeth US’}[data-lid="267450654094"]. Title:after{content:’8Pcs/Set PA14-1/2 HSS Bore 22mm 14.5° Involute Gear Cutter DP12 DP20 Kit Tool US’}[data-lid="267086225909"]. Title:after{content:’1X Milling Machine Part R8 Draw Bar Overall Drawbar M7/16 For Bridgeport Mill’}[data-lid="267163780144"]. Coupon:before{content:’10%’} [data-lid="267534255160"]. Title:after{content:’USB 3/4 Axis 6040/6090 CNC Router Engraver VFD Engraving Milling Drill Machine’}[data-lid="267534255160"]. Title:after{content:’Milling Machine Part 7/16 Thread R8 Draw Bar Overall Drawbar For Vertical Millin’}[data-lid="267535186490"]. Title:after{content:’1X Milling Machine Part R8 Draw Bar Overall Drawbar M7/16 For Bridgeport Mill’}[data-lid="267100976256"]. Coupon:before{content:’10%’} [data-lid="267177134741"]. Title:after{content:’Bridgeport Milling Machine Switch 3 Phase AC Motor Forward Reverse Mill Switch’}[data-lid="267177134741"]. Coupon:before{content:’10%’} [data-lid="267237968057"]. Title:after{content:’Bridgeport Milling Machine Switch 3 Phase AC Motor Forward Reverse Mill Switch’}[data-lid="267237968057"]. Coupon:before{content:’10%’} [data-lid="267191605435"]. Title:after{content:’1X Milling Machine Part R8 Draw Bar Overall Drawbar M7/16 For Bridgeport Mill’}[data-lid="267191605435"]. Coupon:before{content:’10%’} [data-lid="267541762284"]. Title:after{content:’2-seat Waiting Chair Reception Room Guest Chair Bank Airport Bench +table’}[data-lid="267541762284"]. Title:aftercontent:’H1503 15\\.

Comments Off