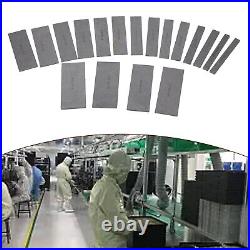

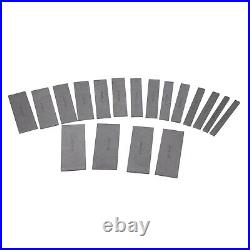

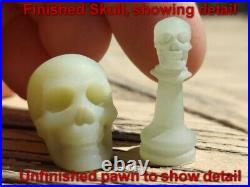

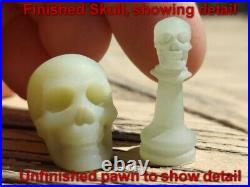

The pictures show the machining of G10… For those that may not be aware of what G10 is, here’s what you need to know in a nutshell. G10 is NOT a plastic. It is a solid lamination made from hundreds of layers of glass and or carbon fiber sheets, pressed, and heated with a phenolic resin binding them together. Although it’s harder than most metals, it has roughly the same machining characteristics as aluminum or other non-hardening metals… Thus, it is many times stronger, denser, harder to work and thus superior to any plastic, including polycarbonate. Machine size (footprint): Length = 37″, Width = 31.5″, Height = 28, not including the standard sized control box. More than twice the weight of hobby grade machines. Frame Material: 5/8 steel Gantry and supports with aluminum in non critical areas, bed etc. Bed: Heavy duty T slotted aluminum, 750mm 450mm (about 29.5″ X 17.7″), work area is about Y-600mm X-400mm Z-100mm (about 23.6″ X 15.7″ X 4)… With minor adjustments to the spindle in it’s sleeve, the maximum material size that can be placed on the bed and worked on is 30″ – 18″ – 6. Input Power: custom ordered in 110 volt, with hookups in control box… Allows for greater utility and no need for an electrician to install 220v outlets. Spindle: 80mm diameter, 4 bearing stabilized 3 horsepower (2200w), runs up to 24,000 rpm. Collet: ER20 shaft, collared for ER20 size spring collets… Two stainless steel ones are included. Accuracy (chatter): less than 0.0001. Stepper motors: X Y Z axes are all industrial duty closed loop (5742 two-phase 4 wire), for extreme accuracy and repeatability. (Z axis motor needs to be bolted on after unboxing machine, takes just a couple minutes with the included allen wrenches). Limit switches on all axes… (you will have to connect the wires for the Z axis after unboxing). Basin bed enclosure: Custom ordered Water basin is Stainless steel with a drain at back for recycling the water or other coolant, basin can also be filled for cutting underwater, helps eliminate dust and chips from being thrown everywhere. High precision direct drive 1605 ballscrews with backlash prevention on all axes. Precision flat ground linear rails on all axes for the linear bearings to ride on instead of tubes that sag, gives added stability and accuracy… No dip for the Z axis in the middle of the bed, like on every other machine we’ve had in the past. Coolant System: 2 pumps included, 1 for the the water cooled spindle, 1 for coolant when cutting metal. Control: Control box has machine controller built in, load gcode files with (included) micro SD. Runs G code/TAB files/nc file/NCC files/DXF file/GERBER file… No additional computer needed… Can be CNC controlled or manually jogged and controlled. Includes: Everything to get you started right away. Two water/fluid pumps, ER20 spring collets in 1/8″ and 1/4″, crescent wrenches for changing bits, bit assortment, tools for tightening bolts, hold down clamps, T bolts, SD card, and a few other things you might find useful. Video of a machine just like this one in action, carving a perfect skull from a grain of rice! You may not realize it, but there’s a HUGE market for these tiny skulls… It only takes a few minutes to make one… Put it in a 35¢ rice pendant bottle and sell it for 10 dollars….. And I’ll even include the. Nc gcode file if you’d like me to… Just one idea of the many thousands of things you can make with one of these machines… It truly is a “business in a box”. Video of how to use the control system/DSP. We make slingshots and other things that go along with them for a living using machines just like the one you’ll be purchasing… Thought I’d need 10, but because these are so fast and efficient I actually only need five.. It’s important for you to understand that we bought these machines to use… Just need to clear up some space for inventory and such. These were custom ordered and are designed and built from the ground up for utility, ease of use and real industrial, professional use. Made to run for years with no problems. They do not have closed loop systems, so have low levels of registration repeatability, they are not made to professional standards and will not stand up to continued use… I’ve been down that road and know it for a fact. Over twice what hobby machines weigh. More weight means it’s made from thicker, stronger and better materials. Which also means it has more inherent stability and strength. Bed is fully enclosed in a stainless steel basin for holding water with a drain at back… Allows for the option of cutting underwater… When filled, the water further increases weight for even more stability, and makes for much quieter cutting, and makes it possible for zero dust when cutting materials such as carbon fiber or G10. Also a lot less mess and easier cleanup when cutting metals such as aluminum because the chips don’t fly all over the place, they’re contained. In other words, if you run the machine with the water in the basin, you can cut hard and hazardous materials without worrying about dust getting all over everything and cleanup is much easier. Of course if you don’t want to cut underwater, there is a water cooling pump and adjustable spray nozzle included as well, the sink will contain the water from that or excess water can be drained away, either way. And of course you don’t have to use that either, if you don’t want to cut dustless, like if cutting a wooden piece… In which case, if you want to, you can hook up your air compressor and blow the chips away instead of using water. That means this machine is inherently more precise and can absolutely run for days or even weeks on end, and still not get that annoying zero drift you get with ALL open loop systems. There are industrial grade Closed Loop stepper motors on all three axes. Closed loop means you don’t get the zero point drift like you get with EVERY open loop hobby machine.. With a hobby machine that has an OPEN loop system; you drill a registration hole at your zero point, after using the machine for a while you might want to check registration, so send the bit to zero… But your bit doesn’t line up precisely on the registration hole… Depending on how much time, and hardness of material being cut the lineup may be off by quite a bit. Whereas a Closed loop system will be dead on center of hole after any amount of time no matter how large the workpiece or how tough the material being worked on. Open loop systems do not have an internal verification system (feedback loop) to know how far or how many steps were actually taken, they basically go by amount of power used equals a certain number of steps, not really measuring actual distance moved… So if cutting into hard materials, an open loop system will typically miss or lose steps because it expended the correct amount of power to go a certain amount of steps, but it actually did not because the material is harder and requires more power to go the same distance as cutting a softer material… In other words, it may have moved the correct distance if cutting a light wood or plastic, but if cutting something like aluminum or G10, it takes more power to go the right amount of steps and open loop systems don’t have a way to compensate for that. As the step count error accumulates over the course of a project, it will give distorted results… Like elongated holes, or instead of straight sides they angle and step down and so forth. The harder the material, and more time/lines of code, the greater the distortion…. Most people are fine with this, as it’s usually not that bad when working with light materials. But if you want truly professional results and have high standards, this is not acceptable. With a closed loop system, like this machine has, an incorporated feedback loop verifies the correct amount of steps (regardless of power used) have been taken for every called for action in your Gcode, thus, as it works even on the hardest of materials, it correctly and continuously counts it’s steps and makes sure it goes the proper amount of steps/distance called for in the gcode… So at the end of your project, when you tell it to go to the registration hole, it will be dead center of it. This is especially useful when doing 3D work on flat board material, because when you flip the piece using a closed loop system, no compensation is required… The registration hole is exactly where your zero needs to be. As a result of the step count always being correct, holes will be the right shape, straight sides will be straight and flat, no distortion. Closed loop systems are the real secret to getting professional results. The machine also has it’s own built in operating system on the operation console box. This means no expensive dedicated computer or additional software is needed to run your files… A lot less cost to you, more dependability, easier to work with and use. The integrated DSP is much easier to use than pretty much any other operating system I’ve ever used, and it’s also more stable. We’ve tested it out by using one of these machines for over 6 weeks straight with no resets or turning off the machine, and it never faultered… Which is quite different than Mach 3 and the like, which seems to need resetting pretty much every 24 hours on every computer system I’ve used it on. All wiring is heavy gauge copper, not aluminum like in so many hobby grade machines. A built in transformer allows for 110v common household current, no need to call an electrician. Makes it easy to set it up wherever it’s convenient for you. Or if setting up several machines at one location (like we did) it’s easy to get electricity to them all. In short, this is a professional industrial duty CNC Gantry Mill machine, that can take on all sorts of jobs, from titanium to stone to G10 to micarta to brass to steel to plastic… Yet has such extreme precision it can carve a perfect 3D skull from a grain of rice (rice is so delicate it’s actually harder to do than cutting it out of steel). Here is a video of one of our machines carving a 3D skull from a grain of rice, complete with intact septum and tooth detail…. Now THAT is PRECISION… And what’s more is this thing is actually capable of more than 10 times more precision than that, but you’d need some truly special bits, and of course a microscope to see it though! Whatever you need cut, etched or shaped… These machines are up to the task. They can handle steel, titanium, bone, antler, aluminum, G10, carbon fiber, basically pretty much anything you want… Just know, Only professional, heavy duty, machines with big spindles and closed loop systems can give you the results you’re looking for if you want truly professional results, and this is that kind of machine. Pictures are of machines that are already being used in my workshop. Because of the size and weight… And only in the Continental United States. This is a VERY good deal for the right person or people… You can be making products for sale almost immediately after that. Take your future, make it what you want it to be. With just a little creativity and the will to make it happen, you can insulate your life against problems like we’ve already been experiencing recently in the world, and against the unknown and unforeseen as well. You will never be called “non essential” again! Video of it in action, carving a grain of rice! Video of how to use the DSP. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “pocket_predator” and is located in this country: US. This item can be shipped to United States.

- Spindle Horsepower: 3 hp

- Machine Type: Milling Machine

- Power Source: Electric

- Custom Bundle: Yes

- Table Length: 35 in – 39.9 in

- Z-Axis Travel Bed: Less than 10 in

- Table Width: 20 in – 24.9 in

- Brand: Blue Ox

- Function: Milling, Drilling

- X-Axis Travel Bed: 21 in – 25 in

- Control: CNC

- Model Year: 2021

- Max Spindle Speed (RPM): Over 15000

- Voltage: 110 V

- Y-Axis Travel Bed: 26 in – 30 in