2025

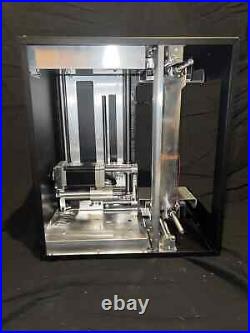

Sharpe mill

COMES WITH R8 COLLET SET VISE CUTTING TOOLS.

Comments Off

ER16 Chuck Collet for Emco Unimat 3/4. 10 pcs Collet spring. Goods will only be accepted for return if they are despatched within 14 days of delive.

Comments Off

Mill & Cut aluminum and even steel along with wood, plastics, etc. Currently out of stock everywhere and very difficult to find one for sale. Experience precision and versatility with the DD GG3-S Desktop CNC Mill, a state-of-the-art horizontal milling machine designed for multipurpose use. Its electric power source ensures consistent performance, while the CNC control allows for accurate and efficient operation. Whether you’re a hobbyist or a professional, this machine is compatible with both Mac and Windows systems, making it easily programmable for a variety of projects.

Comments Off

2002 HAAS VF-3B CNC Vertical MACHINING CENTER Mill. Have two warehouses full of used equipment and tooling, and always getting new inventory.

Comments Off

Applications This DRO kit is commonly fitted to machines, especially for metal working – lathes, cylindrical grinders, milling machines, surface grinders, boring mills and other machine tools – to allow the operator to work faster and with greater accuracy. Use of DROs is not limited to manually operated machines. CNC machines can usually be switched to manual operation, and in this case a form of DRO is simulated on its control panel. Jewelry Design & Repair. Digital Readout& Linear Scale. Welding & Soldering Tools. Rosin Heat Press Machine. 2 Axis Digital Readout DRO Kit 5µm 250mm&1000mm TTL Linear Scale CNC Mill Lathe. This DRO kit is. Commonly fitted to machines, especially for metal working – lathes, cylindrical grinders, milling machines, surface grinders, boring mills and other machine tools – to allow the operator to work faster and with greater accuracy. 2PCS Linear scale 250mm+1000mm (10″ & 40″). 1PCS 2Axis digital read out with holder and mount bracket. 2PCS Mounting base for scales. 2PCS Protective cover for scals some screws for scales. So to accomplish a perfect project. To offer excellent long-distance viewing. DRO providing a two axis display with pitch circle calculator, diameter/radius conversion, absolute and incremental toggle, and inch metric toggle. Digital readout kit can avoid wasting weeks to check machine precision. Lifetime free technical supp. Readout allowable input signal. Allowable input signal frequency. Less than 5M Hz. Max resolution of digital display length. 5µm(0.005mm/0.0002). Min resolution of digital display angle. (11.2″7″2.8). Backup data for power fail. Power off Memory by E2PROM for ten years. Q1 : are the length 300MM, 900MM travel length or total? Answer : all are travel length. Q2 : what does the dro measure to? Answer : measure to 0.005mm, 0.0002inch (1inch=25.4mm). Q3 : Can i cut the scales by myself? Answer : Technically NO, it maybe unavailable after cutting. Q4: Do you have English user manual? Answer : yes, it comes with the dro box. Q5: Do you have other cheaper types, such as measure to 0.001mm? Q6: Is it easy to mount these scales and dro? Answer : Please must check the scale pin definition (1,2,3,4,5,6,7,8,9), which is very important!! Q8: How to switch between milling machine lathe grinding machines. How to switch Mill type to Lathe type? Answer : Please see the following video. (press 6 times after DRO powers on). Q11 : How to set. Radius to Diameter Mode? Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Like LCD screen, industrial burner accessories, printer accessories, instrument accessories, and other fields solutions, we supply Sumsung, LG, AUO, Xinje, Riello, Honeywell, Dungs, Mitsubishi, Siemens, Heidelberg machine parts and The international famous brand accessories etc. Due to time zones, our reply to your questions may not be immediately. But within above working time, we w. If it’s non-workdays, please kindly be patient and wait till Monday.

Comments Off

Bosch Heavy Duty Replacement Motor For Renz Schaber Power Scraper 110 Volt New.

Comments Off

This item is brand NEW and 100% authentic. All our products are 100% authentic! – We guarantee your complete satisfaction and always wish for your happiness. If you have any questions or if there’s any specific item you’re looking for, please let us know anytime! International Buyers – Please Note. Thank you for your understanding.

Comments Off

Cs-head{overflow:hidden;position:relative}. Title{margin:0;font-weight:400;font-size:14px;padding:5px 10px}. Dc-dock:hover{width:117px;background-position:bottom right}. Dc-cs{clear:both;max-width:100vw}. Dock-rb{right:0;bottom:0}. Title{font-weight: 700;font-size: 24px}. Title:after{content:’Hot Sale’;color: #FFFFFF}. Cs-list>li:nth-child(n+7){display:none}. Title{margin:0;font-weight: 700;font-size: 24px}. Title:after{content:’You may like’;color: #FFFFFF}. Coupon{transform-origin:right top;right:0}. Cs-list{margin:0 0 0 -20px;padding:0;background:#FFF}. Cs-list:before{display:table;line-height:0;content:}. Cs-list:after{clear:both}. Cs-list>li{float:left;width:16.66%;list-style:none;box-sizing:border-box;padding:10px 0 10px 20px;position:relative;margin:0}. Cs-list-col6>li{width:16.66%}. Cs-list-col7>li{width:14.28%;padding-left:18px}. Cs-list-col8>li{width:12.5%;padding-left:16px}. Cs-list-col9>li{width:11.11%;padding-left:15px}. Cs-list-col10>li{width:10%;padding-left:14px}. Cs-list-col11>li{width:9.09%;padding-left:12px}. Cs-list-col12>li{width:8.33%;padding-left:10px}. Cs-list>liwidth:33.33%! Cover:after{display:block;content:”;padding-top:100%;background-repeat:no-repeat;background-size:cover;background-position:center}. Cs-list a{text-decoration:none}. Title{color:#333;margin:5px 0}. Title:after{display:block;display:-webkit-box;-webkit-line-clamp:2;-webkit-box-orient:vertical;font-size:14px;line-height:1.4em;height:2.8em;overflow:hidden;white-space:normal;word-break:break-word;-webkit-hyphens:auto;-ms-hyphens:auto;hyphens:auto}. Plus{height:20px;overflow:hidden}. Price:after{content:”;font-size:14px}. Origin{margin-left:3px;font-size:12px;color:#AAA}. Origin:after{display:none;content:”;text-decoration:line-through}. Coupon{display:none;width:60px;height:60px;border-radius:50%;background:rgba(224,13,12.8);color:#FFF;position:absolute;top:10px;right:10px;text-align:center;padding-top:12px;box-sizing:border-box}. Coupon:before{content:”;font-size:20px}. Coupon:after{content:’Off’;font-size:12px;position:absolute;bottom:8px;right:12px}. Title{min-height:12px}p:empty+hr{display:none}hr+span. Dc_tracker_img{display:none}#ds_div>. Dc_tracker_img:last-of-type{display:block} [data-lid="365263565126"]. Title:aftercontent:’50 Pack T316 Stainless Steel Tensioner Set for 1/8\\.

Comments Off

Sunglasses with Gold Mirror lenses. All original Gucci packaging and casing is included such as cloth, case and sleeve. Brand new in the original box.

Comments Off

3 Axis CNC 6050 Milling Carving Engraver Router Machine Engraving Machine 500W. Our sophisticated engraving machine stands as a pinnacle of craftsmanship, poised to serve as an invaluable aide in your artistic endeavor of carving. With its precision-engineered design, it transforms mere materials into intricate masterpieces, elevating your woodworking craftsmanship to new heights. This elegantly crafted tool doesn’t merely shape wood-it breathes life into your vision, harmoniously fusing artistry with technology. Build to Last: It is composed of high-quality aluminum alloy with a sandblasting anodizing process, which makes it rust-resistant, sturdy, and has a long service life. Powerful Function: It uses a 57-76 stepper motor with a power of 500W and a speed of 10000rpm, which can efficiently and accurately carve according to your carving needs. Thoughtful Design: It adopts XYZ three-axis and easy-to-use integrated control box, with speed regulation, E-Stop, and Reset functions, which can better present your carving skills. In addition, it supports the Windows XP/7/8/10 system, making it easy for you to connect to a computer for precise engraving. Safety Protection: It has an air cooling design and an emergency stop switch, which can ensure timely heat dissipation, as well as the stability and use safety of the product during operation. Enjoy DIY: With it, you can do your own woodworking or plastic DIY to create your favorite works and enjoy the creative process! Ideal Gift: Because of its practicality and powerful functionality, you can give it as a Christmas, Thanksgiving, or Halloween gift to your worker friends. Protective Package: We have used sponge wrapping to minimize damage to the product during transportation. It is our pleasure to answer your confusion and questions. Sturdy Collet: You can mount the drill bit(not included) securely for engraving. Chain Design : The drag-chain cable design is not easily tangled and more beautiful and simple. It is compatible with laser heads and trimmers. It applies to Windows XP / 7/8/10. It can be used in factories, woodworking, workshops, advertising shops, etc. It is suitable for carving wood, aluminum, brass, organic glass, PCB, MDF, acrylic, resin, nylon, carbon fiber, PVC, etc. Color: Blue and Black. Plug Type: US Standard. Maximum Feeding Height: 115mm/4.53in. Y-axis Travel: 600mm/23.62in. X-axis Travel: 500mm/19.69in. Z-axis Travel: 120mm/4.72in. Y-axis Transmission: 1605 Roller Screw/15 Square Rail+Slider. X-axis Transmission: 1605 Roller Screw/15 Square Rail+Slider. Z-axis Transmission: 1204 Roller Screw/15 Square Rail+Slider. Z-axis Drive Motor: 57-76 Stepper Motor. Y-axis Maximum Operating Speed: 1500mm/59.06in/min. Z-axis Maximum Operating Speed: 1200mm/47.24in/min. Spindle Motor Power: Air-cooled 500W. Spindle Motor Speed: 10000RPM. Spindle Motor Collet Model: ER11. Spindle Motor Collet Camping Size: 1-7mm/0.039-0.276. Control System Data Transmission Method: USB. Machine Size: 88.877.355.5cm/34.9630.4321.85in. Workbench Size: 78.4 60.6cm/30.8723.86in. Package Size: 937316cm/36.6128.746.3inch. Gross Weight: 24.3kg/53.57lb. Net Weight: 24kg/52.91 lbs. YSB8SU-000200US(Frame and Machine). Package Size: 8349.524.5cm/49.519.499.65inch. Gross Weight: 24.6kg/54.23lb. Net Weight: 24kg/52.91lb. 1 Air-Cooled Spindle Motor. Other Accessories for Use. Please be patient as all parts arrive. Please allow the slight color difference caused by the shooting light and 1-3 cm error due to manual measurement, and make sure you do not mind before ordering. Router Engraver Milling Machine. Spindle Motor Collet Model. Spindle Motor Collet Camping Size. Control System Data Transmission Method.

Comments Off