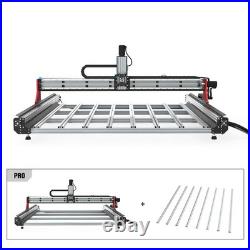

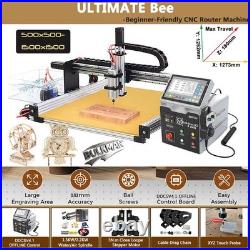

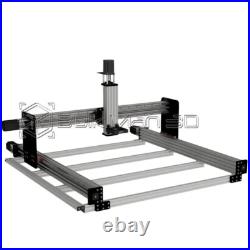

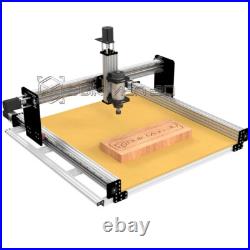

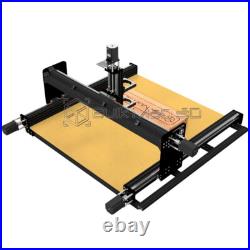

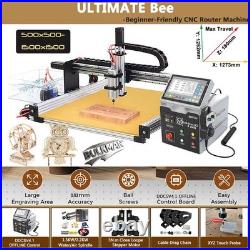

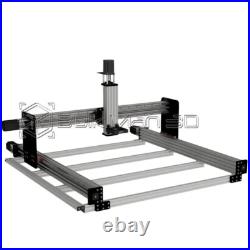

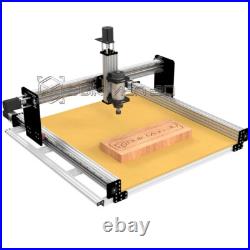

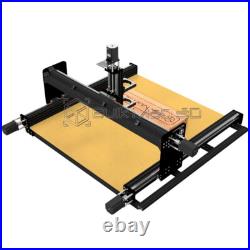

The BULK-MAN 3D ULTIMATE Bee is a solid and reliable CNC Machine. Featured by HGR Rails and Quiet Transmission Ball Screws! The ULTIMATE Bee CNC excels at cutting through plastics, foam, softwood, hardwood and even soft metal such as aluminium and brass. The ULTIMATE Bee is our second CNC Machine based on the initial QueenBee PRO design lineage, which is characterised by the use of C-Beam. Extrusions and the rectangular-shaped Y-Plates. It is 100% fully self-developed, designed by BulkMan3D International R&D Team and copyrighted by BulkMan3D. Frame Structure: 4 Axis Transmission: SFS1210 Ball Screw + HGR Linear Rails Maximum Supported weight of Z-Axis(spindle): 6kg Maximum Cutting Area(Tested with? 80 1.5KW spindle): – Z-Axis: 150-180mm/5.9-7.1inch – X-Axis: 1270mm/50inch – Y-A. ULTIMATE Bee CNC Router Machine Full Kit with DDCSV4.1 Control Box. BULK-MAN 3D ULTIMATE Bee. Is a solid and reliable CNC Machine. HGR Rails and Quiet Transmission Ball Screws. Bee CNC excels at cutting through plastics, foam, softwood, hardwood and even soft metal such as aluminium and brass. Is our second CNC Machine based on the initial QueenBee PRO. Design lineage, which is characterised by the use of C-Beam. It is 100% fully self-developed, designed by BulkMan3D International R&D Team and copyrighted. Transmission: SFS1210 Ball Screw + HGR Linear Rails. Maximum Supported weight of Z-Axis(spindle): 6kg. Maximum Cutting Area(Tested with? 80 2.2KW spindle). Z-Axis: 150-180mm/5.9-7.1inch. Y-Axis: 1250mm/49.2inch. ULTIMATE Bee Mechanical Kit. Quiet Transmission Precise SFS1210 Ball Screw. Cable Drag Chain System. Spindle Bundle Kit with Dust Cover. 2.2KW Water-Cooled Spindle (High Speed 7 Series 4 Bearings). Controller Bundle Kit (Including Wiring Cable Kit) with Stepper Motors. DDCS V4.1 4Axis Offline Control Box System with MPG Handwheel. Drag Chain System is already included in this machine design and no need to be added after! The Ball screw nut fixing and dismounting requires professional tools or done by professional stuffs! Never rotate the ball screw nut over the ball screw end! This is very important as if the ball bearings come off the ball nut the ball screw will not work. You will void any. Free Gift-10PCS Drill Bits (Optional). Diameter:0.6-1.5mm. Diameter 0.5-3.175mm. Diameter 2.1-3.05mm. It’s default to send1.5-6mm drill bits for free, please leave us a message if need other sizes. ULTIMATE Bee Breif Introduction. Bulk-Man 3D is the largest wholesaler of Open Source CNC parts worldwide. By producing or sourcing parts directly from the factory. We eliminate the “middle man”, and in doing so, we can provide the best wholesale price direct to the public! After many CNC owners and members of the community approached us requesting a linear rail solution for their machine at an affordable price. Our technicians worked hard researching different options available and ways we can improve on existing designs. The result of the project was. Carrying on the tradition of community engagement, CNC owners and members wanted more, our technicians went back to the drawing board. Researching more improvements based on community input, the resulting machine is the. Mainly distinguishes itself from the first design, the. By having Ball Screws as a transmission system instead. Of the traditional ACME Lead Screw. The Ball Screw has high-efficiency levels, delivering more torque to the motor when compared to an ACME Lead. Screw used in the. Is not only a machine capable of cutting through a wide diversity of materials. The ULTIMATE Bee excels at cutting. Compatible Material for Cutting/Milling/Engraving. Aluminium / Hard Wood / Soft Wood / Oak / Plexi Glass / Delrin / HDPE / Foam. Drill Bits & Milling Cutters. The ULTIMATE Bee can create intricate 3D carvings like wood artware, inlays, adverting logo, plaques. Furniture, amazing art works and so much. All the widely used applications can be achived here! Recommended Waste Board Dimensions(mm). The ULTIMATE Bee was designed by our team of engineers with a great amount of thought into each aspect of the machine. Each of the components used. On our machine are designed to be paired with each other in order to create a perfect ecosystem which results in the ULTIMATE Bee CNC Machine. Don’t be tricked by other companies who claim a larger ball screw, more rails/ bearings, or different rail positioning will make their machine better than the. These are presumptions made with no engineering reason or facts by salesmen, not engineers. By researching the specifications of the. Components, you can conclude that in fact larger ball screws, more rails/bearings, different rail positioning all reduce a machine’s performance. Ball Screw Size Engineered For Our Machines. The ULTIMATE Bee features a 12mm Diameter Ball Screw. The 12mm Diameter Ball Screw was carefully selected by our engineers to make the most of a NEMA 23 stepper motor. Just by having this smaller diameter than a 16mm Ball Screw, it reduces the load on the motor by 25%. In other words, when the NEMA 23 Stepper motor is paired with the 12mm Ball Screw the motion motors drive through tougher materials with up to 25% more torque than the same motors paired with a 16mm Ball Screw. Why Do You Get More Torque Out of a 12mm Ball Screw? The reason is very simple: the further you apply the force to the pivot point, the more impact this force will have on the pivot object. On a CNC, the stepper motor shaft is the pivot point, and the distance where the force is applied to the shaft is determined by the diameter of the Ball Screw. The analogy in the image below helps explain why a smaller diameter Ball Screw can be more effective. Bigger Ball Screws are recommended when they are designed to work with larger motors such as NEMA 34, or AC Servo motors for the transmission system to compensate for the extra torque required. Machines of this caliber would also use cast and milled steel frames rather than aluminum profiles. A Ball Screw larger than 12mm should not be used in a design where the motors are NEMA 23. What About The Vibration On a Smaller Diameter Ball Screw? Keeping low-vibration levels in the transmission system is extremely important for a CNC Machine. Due to this, we have paired the ULTIMATE Bee with a 10mm pitch Ball Screw instead of a usual 4mm pitch for the X and Y-Axis. This change has significant results, making the CNC travel more with smaller Ball Screw rotations, thus, reducing the Ball Screw vibration at fast feed rates. Our engineering tests conclude: A 12mm ball screw has the perfect balance of torque and vibration when paired with a NEMA 23 motor in a CNC Machine size 1500x1500mm or less. Larger Ball Screws are an incorrect design for NEMA 23 Motors. That is why the ULTIMATE Bee is the best design of its kind! 2 Rails Is Better Than 4. Simpler Design, Better Results! The correct number of linear rails and bearings were selected by our engineers to increase performance. The HGH15CA bearings used on the X and Y-Axis were designed to have the correct spacing between them when mounted to a 20 series profile. The Y-Axis each utilise a single HGR15 linear rail with 2 x HGH15CA bearing carriages on the gantry plates. In a system where only the friction caused by bearings is considered, having double rails and bearings on the Y-Axis as per the image below will add an additional +100% of the amount of friction, therefore, more motor power will be required. If you pair this with any minute misalignment of a bearing or rail during installation, the force required by the same motor to move 4 bearings will result in loss of motor power which is translated to a loss in performance. Of a machine that uses 2 rails (4 bearings) on one actuator. Because the X-Axis gantry carries the Z assembly the moment loads (MR in particular) are distributed by using 4 x HGH15CA bearing carriages and 2 x HGR rails. The Z-Axis uses 2 x MGN15 Linear Rails and 4 x MGN15C carriages spaced to obtain maximum. Possible resistance to the operational moment loads (MP in particular). In other words, we reverse engineered the forces that the Z-Axis is subjected to during a cutting operation, and then, calculated the necessary spacing between MGN bearings for the Z-Axis. NOTE: The position of the Ball Screws, Linear Rails and Bearing Carriage are designed for optimal positioning on all axis (Y, A, X and Z) – another. Example of Bulk Man 3D engineering innovation. Opposite bearing designs are a flaw. The opposite bearing design implemented by other competitors is an inferior and incorrect engineering design for the X-Axis. The correct design is where th. E rails and bearings are on the same face because the bearings are less susceptible to twisting from moment forces when paired with another set of. The opposite bearing design is more susceptible to twisting especially when paired with heavy spindles such as the 2.2kW. The moment force subjected t. O the bearings in this configuration will induce more runout, meaning worse tolerances compared to a stronger and correctly engineered design that has bearings on the same face. Correct Couplers Used In ULTIMATE Bee Design. Double diaphragm couplings are designed for ball screws while jaw couplings are not designed for ball screws. Double Diaphragm couplings are more efficient than Jaw Couplings when paired with ball screws as they are designed for zero backlash. The diaphragm coupling design uses metal plates rather than plastic, making them more reliable and yield a longer service life. The double diaphragm coupling allows for higher speed and vibration dampening in the system which is essential for high performance and smooth running of the CNC. Smooth operation with little to no vibration will mean smoother and high-quality cuts. A design which uses a Jaw Coupling with a Ball Screw is an incorrect engineering design and will produce poor finish on the work piece. Ball Nut Gaskets Reduce Vibration and Binding. Giving the ball nut a vibrational buffer in the form of a rubber gasket, the. Ball screw remains centered by damping the vibrational forces acting on. This provides precision results and prevents the axis from. This small addition make the ULTIMATE Bee a far more effective system. In order to get the most out of your machine without the worry of damage. Or chatter on your workpiece. Upgradeable Motors Achieve Commercial Speeds. Our ULTIMATE Bee CNC has options to have its motors upgraded to achieve high-speed operation similar to industrial machines. Very few machines can. Match the rapids speeds of up to 30,000mm/min like the ULTIMATE Bee can with servos. This means much faster workflow and more jobs done. Our Servos offer higher levels of accuracy and can be programmed to get the most performance out of your CNC, so you will not need to upgrade for a f. Aster machine in the future. M Close Loop Stepper Motors. Step Angle/Phase: 1.8 Degree. Rated Voltage/current: 3.5A. Outlet Mode: single output shaft. Rated Speed: 1000 rpm (no-load speed: 2000 rpm). Outlet Mode: two-phase four-wire (must be wired according to motor label). Extra Z-Axis Height Increases Work Possibilities. Our machines offer 180mm of Z-axis workspace to maximize the working potential. It is easy to mill out large cuts of wood, plastic or aluminium or add a r. When our engineers designed the ULTIMATE Bee we took our customer’s feedback on wanting extra workable height as a main consideration. His way, there will be no need to make. Upgrades or additions later to achieve more cutting depth, or space to add a new rotary axis. The ULTIMATE Bee, The Best and Last of its Kind! Coming from the QueenBee PRO lineage, the ULTIMATE Bee was thoroughly designed to be the best and last of its kind. No need for versions 2, 3 and etc. Said NO to upgrades as everything was. Carefully designed to provide the best possible machine design and performance. As we scoped and advertised, t. His is the truly ULTIMATE Bee. ULTIMATE Bee’ Frame Design Features. After many hours of research and prototyping and also getting feedback from the community, we worked on creating the ULTIMATE Bee. Has many features over previous CNC designs and our team has once again brought an innovating machine to. Some upgrades from the QueenBee PRO to the ULTIMATE Bee include. Ball Nut Bracket Gaskets. Precision laser cut 1.5mm rubber gaskets are used on all Ball Nut mounting. Brackets to allow for easy. Alignment while maintaining a ridged and secure join to the. The Gasket aids in the building by compensating for any minor misalignment as well as. Vibrations during operation (essential in a more ridged drive system). Quiet Transmission Ball Screw Drive System. There are many benefits in using Ball Screws, such as high efficiency and r. High stiffness, high lead accuracy, and many other advantages. Compared with the contact thread lead screws, a Ball Screw adds balls between the nut. Friction of the conventional. Screw is thus replaced by the rolling. Motion of the balls. The ULTIMATE Bee drive system has been upgraded to SFS1210 and. Screws and ball nuts. 10mm pitch SFS1210 is used on all. Noticeable increase in speed while maintaining the ability to be. With measurable repeatability greater than or equal to 0.01mm. The calculated resolution of the Y, A and. ULTIMATE Bee is 0.00625mm at 1/8th micro-stepping. The Z-axis SFU1204 Ball Screws have a 4mm pitch so the Z calculated r. Esolution is 0.0025mm. Ball Screw Resolution vs Microstepping Table. SFU1204 – 4mm Pitch. SFS1210 – 10mm Pitch. By using an SFU1204 with 4mm pitch on the Z-Axis the system is able to maintain its position even while the motors are not energized. Even with heavier. 2.2kW water-cooled spindles! Choice means no more broken bits or spindles falling into stock when powering off. The 2040 Extrusion on the rear of the X-Axis has been replaced with a 4040 t. By adding a 4040 extrusion to the back of a C-Beam Extrusion, the X-Axis is. All plates have been completely redesigned to incorporate better cable. Switches, and allowing for more adaptive i. All of the main plates are made with thick 10mm aluminium. All surfaces where bearing. Have been machined flat to provide a smooth s. Urface for easy and. The Y and A Axis each utilise a single HGR15 linear rail with 2 x HGH15CA. Carriages on the gantry. By using 2x HGR15 linear rails, one on t. He Y and one on. The A-side, instead of 4, this reduces the. Assembly and rail alignments. Without compromise on the performance. We have introduced diaphragm couplers with the ULTIMATE Bee machines. Main benefits of using. Diaphragm couplers instead of standard f. Lexible couplers is that t. Here is significantly less backlash, as well as. Drastically increasing the resolution and r. Epeatability of the system. Diaphragm couplers are also designed to have noise reduction and vibration. Compensation increases the lifespan of the. Hardware used on the transmission system. What are Linear Rails and Bearings? Linear Rails consists of two parts, the rail and the bearing. The Rail is a precision machined strengthened. Steel assembly that has twin. Tracks to guide a bearing (also know as roller) along. When combining the rail with the bearing you achieve low friction and high. Linear motion for loads. Ranging from 1kg to thousands of kilograms. Why use Linear Rails? There are many applications for using linear rails including industry. The benefit of linear rails over other types of linear guides are the rigidity. Rails are designed to withstand force. Applied from loads in all. Directions, unlike other guides that are only. O withstand a load in one direction. Linear bearings use recirculating balls held in place under tensions for. Construction of the bearings make them. Superior to previous wheel. Motion in respect to load capacity, displacement. DDCS V4.1 4Axis Offline Control Box is an industrial-grade CNC control box, and it is a high-performance control system specially designed to meet the needs of industrial manufacturing. Its rugged exterior and state-of-the-art technology ensure precise control of all CNC machine functions. Its adaptability to various machining tasks provides stability and adaptability, making it a reliable partner for excellent machining results. This DDCS V4.1 4Axis Offline Control Box contains all all the hardware for powering and controlling your ULTIMATE Bee CNC machine. 4Axis Offline Control Box System with MPG Handwheel. Hardware Configuration inside this Control Box. 1x DDCSV4.1 Controller. 1x MC Power Supply S800-36V. 1x MC Power Supply LRS-75-24. 1x MC VFD 2.2KW/110V OR 2.2KW/220V. 4x HBS57S Stepper Driver. 1x MC Plug-in Filter CW4L2-20A. 1x MC Wire-lead Filter CW1B-10A. 1x MC 4-channel relay-24V. 1x MC Fan 8025-24V. 2x MC Fan 6010-24V. 1x MC DB37 Terminal Block. Tips: Most Internal cables and modules inside this control box have been pre-connected, just follow our instruction to simply plug this box and it can work for your machine! 2.2KW 110/220V Water Cooled Spindle Kit. Net Weight : 5.3kg. Spec:? 80 x 213mm (Diameter: 80mm x Length: 213mm). High Speed-7 series 4 Bearings. Run-Out Off: Less than 0.005 mm. Collet:ER20 (28pcs:1mm/1.5mm/2mm/2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/7mm/7.5mm/8mm/8.5mm/9mm/9.5mm/10mm/10.5mm/11mm/11.5mm/12mm/12.5mm/12.7mm/13mm). 2.2KW 110/220V Air Cooled Spindle Kit. Net Weight : 5.5kg. “V-Slot” and ” C-Beam” are registered trademarks of OpenBuilds LLC as released under the Creative Commons Licence Attribution-Share.