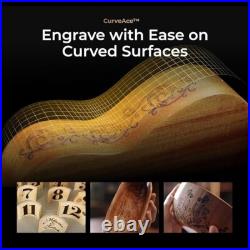

Intelligent Desktop Laser Cutter & Engraver: Thanks to the dual 16MP smart cameras, xTool P2 CO2 laser engraver can automatically construct 3D models of curved objects to make curved surface engraving as perfect as flat, can intelligently recognize shapes to fill pattern on multiple objects and engrave them in one batch. If assembled with the Automatic Conveyor Feeder, xTool P2 also provides the automatic passthrough for precision and convenience when engraving and cutting extra-large materials. Superb Laser Cutting & Engraving : xTool P2 Desktop CO2 laser cutter has a powerful 55W(55000mW) laser tube that allows you to cut 18mm black walnut and 20mm acrylic in only one pass. 3mm basswood can be surprisingly cut at the speed of 35mm/s, 6 times faster than a 20W diode laser. Assembled with a superior motor, the sturdy xTool P2 makes it possible to engrave at an ultrafast speed of 600mm/s. Boundless Creativity: The 26″×14″ large bed size and 2.7 maximum engraving height enrich you with even more possibilities for creations. If with the help of the Riser Base, you can easily engrave on 8.4 objects. Moreover, P2 is also Compatible with RA2 Pro rotary attachment to unleash your creativity on tumblers, mugs, spheres and rings. Create with hundreds of materials: As a smart CO2 laser cutter and engraver machine, xTool P2 has ultra-high absorption efficiency on most materials, perfect for cutting acrylic of all color, wood, leather, MDF, rubber, fabric, engrave on glass, ceramic, slate, coated metal, anodized aluminum, and more. Safer and Cleaner: Enclosed in design, xTool P2 is equipped with automatic lock, emergency stop button, hydraulic support, fire safety, and multiple warning systems to provide all-around protection for you. With the built-in adjustable air assist and slats, you can unquestionably trust P2′s excellent smoke exhaust system including the 145CFM exhaust fan, which can effortlessly distance the materials from annoying smoke. Note? If the temperature drops below 10°C (50?), please add antifreeze under the guidance in the user mannual. XTool P2 is the Class 4 laser engraver, the laser output power is 55000mW.