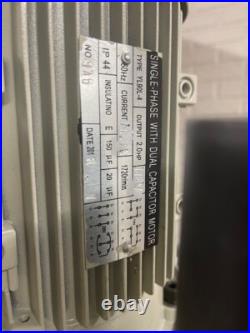

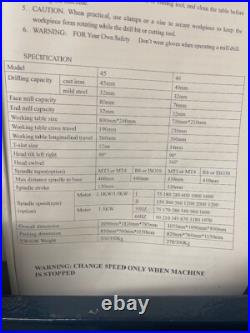

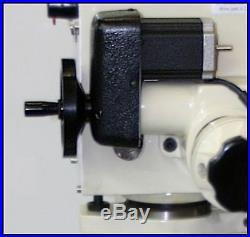

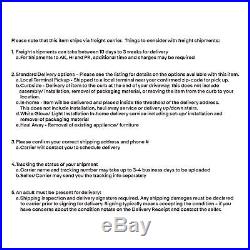

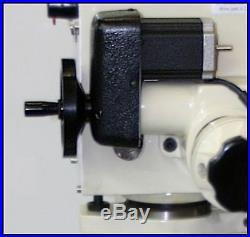

The CNC Express SQ Model has ample 20″ x 9″ travels to accommodate your larger parts! Now with even more powerful motors! The CNC Express SQ is well proven, offers a good size working envelope, runs on 115 or 230 VAC single phase power, has high speed machining, and accommodates coolant, and spindle control. The custom made anti-backlash ballscrews allow precision conventional and climb milling operations as well as accurate circular and contour cuts along any pair of axes without time consuming setups. Offering impressive machining power, repeatability, in a relatively small footprint. The square column CNC Express Milling Machines are available in two sizes, the CNC Express SQ medium size and the extra large CNC Express XL Gearhead models! Compare the specifications and choose the one that is right for you. The Stand, tray and basic accessories are included with the system at no extra charge. Our own custom designed software is complete with built-in graphic test mode and geometry wizards! Other systems use generic 3rd party software and they have no control on features or updates. Precise, powerful, and over 150 in/min rapids! Supports the latest operating systems and includes our advanced USB motion controller! Includes the stand, chip tray, accessories, and professional crating (Domestic orders) all at no extra charge. MN400 Motion Controller (Included in DriveRack). MillMaster Pro for Windows. The latest technology constant current chopping drives used in the. Power electronics result in very high feed and rapid rates, while our fully optoisolated. Motion controller insures maximum reliability with the use of opto-isolated inputs and outputs on. Other systems may use direct connection or a printer port whose reliability is typically not suitable for industrial applications. Since our CNC machines are designed around existing manual machines, they accept standard tools and accessories. This means you won’t have to spend a fortune on specialized or custom tooling. The most commonly needed ones are included with the package for convenience and added savings. We also offer a full assortment of practical tools and accessories to choose from below in the optional accessories section. MicroKinetics CNC systems are expertly built and performance tested to conform to stringent standards. Detailed assembly and testing procedures and checklists are followed to insure consistent, repeatable, high quality machines. CNC Express (Also available). CNC Express SQ (This listing). CNC Express XL (also available). 17.00 (432 mm). 20.00 (508 mm). 28.00 (711 mm). 7.00 (178 mm). 9.00 (229 mm). 12.00(305 mm). 5.00 (127 mm). 4.75 (121 mm). Swivel 360 Degrees 15 7/8 (403 mm). Tilt 90 Degrees Left 90 Degrees Right. 8 1/4″ × 28 1/2″ (210 mm X 724 mm). 9 1/2″ × 32 1/2″ (241.3 mm X 825.5 mm). 9 3/8″ × 39 1/2″ (238 mm X 1003 mm). New Variable Speed 100 to 3000 RPM with included VFD. Torque selectable via gearing. New Variable Speed 100 to 3200 RPM with included VFD. 230VAC 1 PH 10 Amp. 115VAC (230 optional) 1 PH 15 Amp. Floor Space & Height. 42″ Deep ×58″ Wide x 62 Height (1.07 m x 1.47 m x 1.57 m). 46″ Deep ×66″ Wide x 68 Height (1.17 m x 1.68 m x 1.73 m). 50″ Deep × 80″ Wide x 75 Height (1.27 m x 2.03 m x 1.91 m). CNC Express Unique Advantages. More torque where it counts – Our NEW, custom made 750 oz-in motors deliver 41% more torque in bipolar drive method used here plus a 2 to 1 pulley ratio produces over 1500 oz-in of torque at the drive shaft. This maximizes the torque available at the full range of speeds, not just the holding torque. The overall performance with a properly engineered system of mechanics and electronics results in very impressive forces at standstill, at typical cutting speeds and at rapid positioning speeds. Limit switches included in both directions on X and Y and up direction on Z for more convenient referencing and for end of travel without relying solely on mechanical dead stops. Mechanical dead stops provide excellent redundancy which comes into play in the event a limit sensor is not recognized for any reason. While the electronic limit sensors almost never fail, it is great to have this design for setup and testing. Lifetime timing belts that are overdesigned. To never break or need replacement in this application but are important in achieving low vibration and smooth operation. High voltage drivers offer impressive high speed performance (over 150 Inches per minute typical). No thrust bearings – We use high performance tapered roller bearings. Many other competing models use thrust bearings which limit the speed and features or updates. We listen to our customers and add features regularly. Now MillMaster pro offers more G-codes and M-codes than ever, plus Windows 10/8/7/Vista/XP support. Controls and graphically simulates a 3-axis milling type CNC control on any PC running Windows 98/2000/XP/Vista/7/8. The CNC part program can be typed directly into the editor screen, or can be generated via a CAD/CAM program. The interactive mode allows you to see the operation performed graphically as you type each CNC line, aiding in part program development or training. For documentation purposes, you can print the graphics screen and the part program together or separately. True circular interpolation on any two axes and simultaneous linear interpolation on all axes are standard. This allows full 3-D surfacing designs to be run on the target 3 axis machine. Bed mill base system with 2 HP single phase or 3 phase motor. 003 per foot max linear error. Stepper motors (2) 34M750 (1) 23HT350. High performance power Multidriver. Continuous contouring motion controller. G-code control & graphical software. Limit switches, cables, and technical manuals. Included accessories: Cabinet stand with chip pan, shelf and latched door plus the following pictured accessories. 52 Piece Clamping Set. Drill Chuck with Key. 4 Precision CNC Vise. Face Mill with 4 HSS inserts. Covering the front and both sides of the table, this shield provides an added safety measure and retains chips and fluid, keeping the work area clean. The front forward slant design offers improved functionality. No drilling or tapping is needed – the guard mounts easily with two thumbscrews (provided). 6″ and 8″ Vertical/Horizontal. Increases tool life, lubricates metal cutting process and reduces heat buildup. Use with water soluble concentrates and light cutting oils. It comes complete with a tank , pump, 6′ plastic hose, flexible nozzle with valve, and a screen strainer. The pump comes with a 6′ 3-conductor cord with a three- prong plug 110VAC. 110V to 220V transformer available. High Speed Steel 3/8 shank Includes six 2-flute end mills: 1/8, 3/16, 1/4, 5/16, 3/8, 1/2 Comes with wooden organizer stand. 3 Jaw Chuck & Adapter for Rotary tables. 4 Jaw Chuck & Adapter for Rotary tables. High Speed Steel 3/8 shank Includes six 4-flute end mills: 1/8, 3/16, 1/4, 5/16, 3/8, 1/2 Comes with wooden organizer stand. Titanium Coated for longer life High Speed Steel &bull Center Cutting, Single End Complete with wooden storage case 10 pieces 2-flute: 3/16 – 3/4 by 16ths 10 pieces 4-flute: 3/16 – 3/4 by 16ths. Made of high grade steel and precision ground to close tolerance. Sizes: 1/8 to 3/4 by 8ths. R8 Quick Change Tooling. Engineering Quality CNC Components and Systems Since 1985. The free listing tool. The item “New Geared Head Variable Speed spindle Square Column CNC Milling Machine” is in sale since Saturday, July 23, 2016. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “microkineticscnc” and is located in Kennesaw, Georgia. This item can be shipped worldwide.

- Model: CNC Express SQ

- Country/Region of Manufacture: United States

- Spindle Horsepower: 2

- Table Length: 25” – 29.9”

- Model Year: 2018

- Country of Manufacture: United States

- Type: CNC

- Control Type: MillMaster Pro/MN400

- Highest Spindle Speed (RPM): 2501 – 3000

- Make: MicroKinetics

- Table Width: Less than 10”