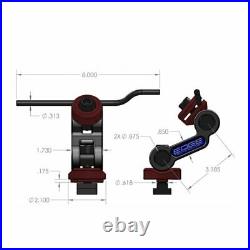

Edge Technology Chuck Stop with a set of 10 hardened parallel bars. 10 sets of hardened parallel bars with case. 0.0002 parallelism accuracy. Parallel bar heights from 1/2″ to 1-5/8″ in 1/8 increments. Strong neodymium magnets secure the Chuck Stop to the chuck face. A centering plug fits the ID of the chuck and keeps the Chuck Stop centered. Included centering plug diameters are 1.4″, 2.0″, 2.5″, 3.0″, 3.5″, and 4.0″The Chuck Stop is 6.0 in diameter. Designed for 3 jaw chucks only. For use on 6 diameter chucks and larger. The Chuck Stop by Edge Technology is designed to locate shorter parts beyond the chuck jaws to provide clearance for facing operations. The Chuck Stop includes 10 sets of different height parallel bars to achieve the required spacing. A centering plug is used to keep the unit centered to the ID of the chuck and strong neodymium magnets secure it to the face of the chuck. Accurately locate parts beyond the chuck jaws to provide clearance for facing operations. We offer full UK support on all the products we sell. Same day despatch on all items ordered before 15:00 GMT. Included centering plug diameters are 1.4″, 2.0″, 2.5″, 3.0″, 3.5″, and 4.0″. The Chuck Stop is 6.0 in diameter. Machine DRO are suppliers of Digital Readout Systems, Measuring Tools, Machine Tools. Established in the UK in 2003 and we pride ourselves on providing top quality tools and equipment with professional customer service and support to both professionals and hobbyists. The item “Edge Technology Chuck Stop with a set of 10 hardened parallel bars” is in sale since Thursday, December 27, 2018. This item is in the category “Business, Office & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “machine_dro” and is located in Hoddesdon. This item can be shipped worldwide.

- Brand: Edge Technology

- MPN: 30-000

- Manufacturer Part Number: 30-000

- Part Number: ME-ED-30-000

- Type: Accessories