2023

10 Most Satisfying Cnc Milling Machines Working Amazing Automatic Factory Machines Technology

Comments Off

Comments Off

Comments Off

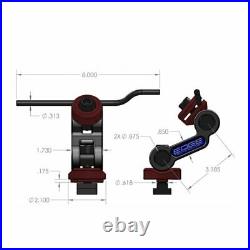

Edge Technology Multi Axis Hardened Stop Rod with 1/2-13 socket head cap. Unique design stays completely below the top surface of vice jaws for cutter clearance. Stop rod stays parallel to the milling machine table so workpiece will contact rod face squarely for increased accuracy. Versatile design allows the 5/16 hardened stop rod to be quickly and accurately positioned. Large 1/2-13 socket head cap screws rigidly clamp the unit in position after adjustments are made. Base of unit is keyed to T-slot in table. The Multi Axis Stop by Edge Technology has a design that stays completely below the top surface of the vise which means it will not interfere with cutting tool paths. It will also keep the stop rod square to the workpiece throughout the entire range of motion. This configuration provides a more consistent locating surface for increased part accuracy. It can be mounted on any available T-slot anywhere along the milling machine table allowing it to accurately locate a workpiece for any type of setup. The Multi Axis Stop is designed so that it stays completely below the top surface of the vice which means it will not interfere with cutting tool paths. We offer full UK support on all the products we sell. Same day despatch on all items ordered before 15:00 GMT. Machine DRO are suppliers of Digital Readout Systems, Measuring Tools, Machine Tools. Established in the UK in 2003 and we pride ourselves on providing top quality tools and equipment with professional customer service and support to both professionals and hobbyists. The item “Edge Technology Multi Axis Hardened Stop Rod with 1/2-13 socket head cap” is in sale since Tuesday, August 7, 2018. This item is in the category “Business, Office & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “machine_dro” and is located in Hoddesdon. This item can be shipped worldwide.

Comments Off

Edge Technology Chuck Stop with a set of 10 hardened parallel bars. 10 sets of hardened parallel bars with case. 0.0002 parallelism accuracy. Parallel bar heights from 1/2″ to 1-5/8″ in 1/8 increments. Strong neodymium magnets secure the Chuck Stop to the chuck face. A centering plug fits the ID of the chuck and keeps the Chuck Stop centered. Included centering plug diameters are 1.4″, 2.0″, 2.5″, 3.0″, 3.5″, and 4.0″The Chuck Stop is 6.0 in diameter. Designed for 3 jaw chucks only. For use on 6 diameter chucks and larger. The Chuck Stop by Edge Technology is designed to locate shorter parts beyond the chuck jaws to provide clearance for facing operations. The Chuck Stop includes 10 sets of different height parallel bars to achieve the required spacing. A centering plug is used to keep the unit centered to the ID of the chuck and strong neodymium magnets secure it to the face of the chuck. Accurately locate parts beyond the chuck jaws to provide clearance for facing operations. We offer full UK support on all the products we sell. Same day despatch on all items ordered before 15:00 GMT. Included centering plug diameters are 1.4″, 2.0″, 2.5″, 3.0″, 3.5″, and 4.0″. The Chuck Stop is 6.0 in diameter. Machine DRO are suppliers of Digital Readout Systems, Measuring Tools, Machine Tools. Established in the UK in 2003 and we pride ourselves on providing top quality tools and equipment with professional customer service and support to both professionals and hobbyists. The item “Edge Technology Chuck Stop with a set of 10 hardened parallel bars” is in sale since Thursday, December 27, 2018. This item is in the category “Business, Office & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “machine_dro” and is located in Hoddesdon. This item can be shipped worldwide.

Comments Off

Comments Off

Edge Technology Pro Tram System With 3/8 Inch Shank Milling Head Square. FULL UK SUPPORT We offer full UK support on all the products we sell. Ask Question SAME DAY DISPATCH Same day despatch on all items ordered before 15:00 GMT Product Features Square the head of a milling machine quickly and easily Simply lower unit to the table and adjust the head until both indicators read the same Sized perfectly to fit the bed of a 6 vise allowing the head to be trammed to the vise instead of the table Can be used with a sine bar or sine plate to adjust the head to precise angles Calibration procedure accounts for any error introduced by worn collets Guaranteed to be equal to or better than any other tramming method or spindle squaring device available Large 2.2 easy to read indicator face Body made from red anodized aluminium Includes calibration gauge and padded case Description The Pro Tram by Edge Technology makes the process of tramming your mill fast, easy and accurate – Tramming is the process of squaring the head of your mill to the table. Most machinists know that if your mill is not trammed properly, surface finishes will be poor and parts will not be flat or square. Most machinists also know that conventional tramming techniques can be tedious and time consuming. The Pro Tram solves these issues allowing you to tram your mill quickly and accurately. To use the Pro Tram simply lower the unit down onto the table and adjust the head until both indicators read the same number. Repeat this process for the opposite axis and you are done. The Pro Tram is also sized perfectly to fit the bed of a 6 inch vise allowing you to tram the head to the vise instead of the table. If you want to spend less time tramming your mill and more time machining parts then you need the Pro Tram by Edge Technology. Key Specifications Shank Size – 3/8 inch. Graduation – 0.001inch. Gauge repeatability – 0.0002 inch. Between Centres – 5 inch. About us Machine DRO are suppliers of Digital Readout Systems, Measuring Tools, Machine Tools. Established in the UK in 2003 and we pride ourselves on providing top quality tools and equipment with professional customer service and support to both professionals and hobbyists. Edge Technology Pro Tramming Gauge for accurately setting milling head square.. We offer full UK support on all the products we sell. Same day despatch on all items ordered before 15:00 GMT. Square the head of a milling machine quickly and easily. Simply lower unit to the table and adjust the head until both indicators read the same. Sized perfectly to fit the bed of a 6 vise allowing the head to be trammed to the vise instead of the table. Can be used with a sine bar or sine plate to adjust the head to precise angles. Calibration procedure accounts for any error introduced by worn collets. Guaranteed to be equal to or better than any other tramming method or spindle squaring device available. Large 2.2 easy to read indicator face. Body made from red anodized aluminium. Includes calibration gauge and padded case. The Pro Tram by Edge Technology makes the process of tramming your mill fast, easy and accurate – Tramming is the process of squaring the head of your mill to the table. Shank Size – 3/8 inch. Machine DRO are suppliers of Digital Readout Systems, Measuring Tools, Machine Tools. The item “Edge Technology Pro Tram System With 3/8 Inch Shank Milling Head Square” is in sale since Thursday, February 9, 2017. This item is in the category “Business, Office & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “machine_dro” and is located in Hoddesdon. This item can be shipped worldwide.

Comments Off

Comments Off

Ultimate Tabletop Milling Machine due to its versatility and precision. This machine was designed for laboratories or small machine shops that need a complete CNC solution in a limited space. It is designed for 24/7 industrial production of small parts in a variety of material including brass, aluminum and soft steel. Travel: X – axis – 16.5″ – 421mm Y – axis – 8.5″ – 217mm Z – axis – 8 – 200mm Servo motors on all axis Linear Guide Ways Ball screw drive system Spindle Speed – 24000 RPM Collets – ER20 Machine Weight – 230lbs Can be fully customized to your needs!!! The item “Tabletop CNC Milling Machine from Levil Technology” is in sale since Tuesday, December 08, 2015. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “levil_technology” and is located in Oviedo, Florida. This item can be shipped to United States.

Comments Off

Tags: control, hypnotic, numerical, technoerotic, technology, video