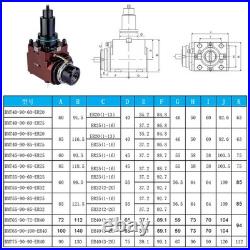

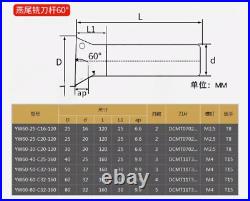

Cnc tool rack multifunctional CNC tool holder CAT40 tool holder(Accessories). The customized service is available with this product. 61.02 21.65 4.72 in. 31.5 9.45 6.7 in. HIGHER QUALITY: LYREIGN The CNC tool holder is made of new material ABS, which has good cushioning and reduces the impact between the handle and the sleeve. The service life of the tool cart will be greatly improved. The entire tool cart adopts electrostatic spraying technology, and has been pickled and phosphated. The CNC tool holder not only looks high-end and elegant, but is also rust-resistant and wear-resistant. Size: 34.6″L x 19.7″W x 60.6H. EINFORCED CONSTRUCTION: The CNC high-capacity tool organizer magazine features an ultra-sturdy triangular structure made from quality-tested cold-rolled steel tubing. The 8-row large-capacity tool holder not only meets storage needs, but also has a strong load-bearing capacity and is not easily deformed after long-term use. The CNC lathe tool rest adopts improved reinforced wear-resistant and anti-slip foot pads to prevent the CNC machine tool rest from tilting due to long-term work. Keep your tools organized and within reach with this convenient tool holder. The equipped parts storage box makes it easy to organize small parts. Tool holder keeper can effectively protect the service life of your valuable tools. SAFE AND ORGANIZED STORAGE: Our CNC tool holder statsion are designed specifically for CNC machine tools, these innovative CNC tool organizers are dedicated to keeping machinists and shop workers safe and protected. With its earthquake-resistant and impact-resistant design, it effectively reduces the risk of accidents in the workplace and protects production lines and users. Rest assured that your tools are well protected and accessible with ease in our thoughtfully designed CNC tool holder stat. EASY INSTALLATION AND AFTER SALE GUARANTEE: All of CNC machined tool holders come pre-assembled. Just follow the installation instructions to install the components and get started. LYREIGN tool box organizer feature stylish design and quality materials. It is best for machine shops, maintenance departments and garages. This cnc tool holder keeper is durable and large-capacity, it can well meet your daily storage needs. Classic, beautiful and elegant, it blends perfectly with its surroundings and leaves a lasting impression. It can bring great convenience to your life. Ideal for garage, warehouse, workshop, repair shop, etc. Product Name: CNC tool holder rack. Material: cold rolled steel. DJ103LC CNC Tool holder cabinet adopts SPCC high-quality 2.0MM cold-rolled steel square tube, and multiple reinforcements are installed to strengthen the structure. The entire cabinet structure is a cuboid, which makes the CAT/BT40 tool holder cabinet very stable. Therefore, most of our BT40 tool racks adopt this structure to increase stability.