2026

1/8 HP Machine Coolant Pump 100mm 4, 110/120/220/240/440/480/575V, Lathe Grinde

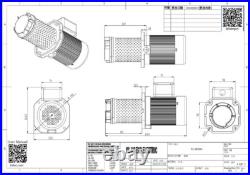

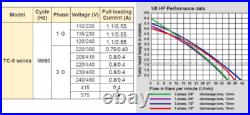

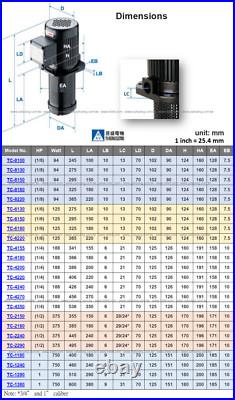

TC Series coolant pump is single stage and developed for spraying of cooling lubricants and the circulation system, especially for machine tools. It is suitable to driver liquids such as water, coolant, light oil and other clean, non-aggressive matters liquid to cooling or lubricant applications. TC Series can be used in machine tools to perform Turning, Milling, Drilling, Cutting, Slitting, Grinding etc. Professional design to perform solid entire unit and high stability. Whole models with efficient filterable strainer. Well design to dissipate operation thermal. Product and design with utility patents. CE & IP54. Patented design to avoid liquid over flooding. Brand: YU HSENG. Phase & Voltage (Low/High Volt) : 1? 110 / 220 V, 1? 120 / 240 V, 3? 220 / 440 V, 3? 240 / 480 V. (Technician default wiring in High Volt). Discharge Bore: NPT 3/8. NPT 1/2″; PT(BSPT) 3/8″; PT(BSPT) 1/2. Length (flange to bottom): 100mm (4). Flow rate in 60 Hz. 1? , 3/8 : 9.2 GPM (35 L/min). 3? , 3/8 : 9.8 GPM (37 L/min). 1? , 1/2 : 10.6 GPM (40 L/min). 3? , 1/2 : 11 GPM (42 L/min). Lift (Head Height) in 60 Hz. 1? , 3/8 : 5.4 M. 3? , 3/8 : 6.0 M. 1? , 1/2 : 5.2 M. 3? , 1/2 : 5.7 M. Pressure in 60 Hz. 1? , 3/8 : 7.7 PSI. 3? , 3/8 : 8.5 PSI. 1? , 1/2 : 7.4 PSI. 3? , 1/2 : 8.1 PSI. Made in Taiwan (Factory Location).

Comments Off