2026

BRIDGEPORT MILLING MACHINE TABLE SCREW END CAPS PAIR X AXIS Handles

USED WITH BEADS DIALS HANDLES BUSHINGS.

Comments Off

USED WITH BEADS DIALS HANDLES BUSHINGS.

Comments Off

VEVOR Milling Machine Power Feed. Our power table feed brings a stable transmission ratio and high load-bearing capabilities. Take control of speed with ease using the manual lever and automatic knob. Ideal for 5/8” end shaft diameter machines and X-axis milling machines. Experience efficiency and reliability like never before! Equipped with Gleason spiral bevel gears, our milling machine power feed ensures a stable transmission ratio, low noise output, high transmission efficiency, and excellent load-bearing capacity. With noise levels? 85dB, providing a conducive environment for your work or study without disruptions. Our power feed table mill is equipped with overload protection. In instances of rapid transmission, if there is a collision or instantaneous reversal between the tool and the workpiece, a special security mechanism safeguards the gearbox’s plastic gears and electronic components from damage. Our compact and lightweight power table feed is easy to install and operate. The control panel features clear functions, making the operation straightforward. Additionally, we provide a detailed installation and user manual, ensuring you have all the information you need to operate effectively. Our power feed milling machine comes with a set of sturdy metal parts that are built to last, including 1 x copper gear, 1 x install the retainer plate, 3 x fixing screws, 2 x limit switch springs, 15 x adjusting shims, 1 x bearing inner ring, and 1 x copper gear gasket. Ultimate High-Compatibility Solution: Our power feed table mill Includes everything needed to mount on most knee-type mills with a 5/8” end shaft diameter that shares the same installation pattern, such as Bridgeport, Precision Matthews, Enco, Jet, Sharp, Acer, Webb, and others. Infinitely Variable Speed Control: With the continuously variable speed knob, you can adjust the speed according to your needs. Our milling machine power feed offers a rated torque of 150 in-lb(16.9 NM), a maximum speed of 200 RPM, a maximum feed rate of 965 mm/min, and a maximum return speed of 1385 mm/min. Highly Stable and Efficient: Featuring Gleason spiral bevel gears, our power table feed boasts stable transmission ratios, low noise, high transmission efficiency, and high load-bearing capacity. Plus, it comes with a special security device that protects the gearbox plastic gears, and electronic components from damage in the event of tool collision or sudden reversal during rapid transmission. Easy to Use, Manual or Automatic: Our power feed milling machine offers two different speed adjustment modes: manual and automatic. With manual control buttons, you can adjust the speed as needed. Alternatively, set the device to automatic constant speed mode for hands-free operation, making your milling tasks a breeze. Designed for X-axis Direction: This power feed woodworking enables smooth movement in the X-axis direction. We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders. Please be aware that. Please DO NOT fill in the PO Box address. California Warehouse: City of Industry, CA. New York State Warehouse: Perth Amboy, NJ. Georgia Warehouse: Austell, GA. North Carolina Warehouse: Grove NC. Oregon Warehouse: AIRPORT WAY Portland, OR. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return. All emails will be responded to within. Special circumstances will be listed clearly in the listing. Please do check everything carefully after you received the parcel, any the damage except DOA (Dead-On-Arrival) would not be covered if it’s your fault.

Comments Off

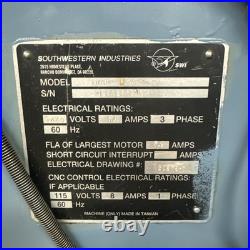

Welcome to Select Machine Tool. SOUTHWESTERN INDUSTRIES TRAK DPM5 Rigid Bed CNC Milling Machine ProtoTRAK SM-3 CNC Control Year: 2002 S/N: 024AS11946 Item #: 05348. MACHINE OVERVIEW Excellent condition TRAK DPM5 Rigid Bed CNC Mill equipped with ProtoTRAK SM-3 Control. Solid, heavy-duty machine ideal for toolrooms, prototyping, and production work. Conversational programming makes it easy to operate without full G-code programming. STANDARD FEATURES. CNC Controlled Ram Motion. Operates as SM-2 or SM-3. Solid Ram Construction for Rigidity. Counterbalanced Ram. Large 3.930 Quill Diameter. Precision Ground Ball Screws. Hardened & Ground Square Ways with Turcite. D. Servo Motors with High Resolution Encoders. Conversational Programming. On-Screen Part Graphics Preview. Automatic Tool Path Generation. Table Load Capacity: 1,320 lbs. Automatic Lubrication. MACHINE SPECIFICATIONS. Table Size: 12″ x 50″. X Travel: 40″. Y Travel: 20″. Z Travel: 23.5″. Spindle Diameter: 3-15/16″. Spindle Taper: 40 NST. Spindle Speed Range: 70 – 3,950 RPM. Quill Travel: 5. Quill Feeds. 006 IPR. Head Swivel: 90° Right & Left. Spindle Motor: 5 HP. Machine Weight: 4,400 lbs. Hardware. Pentium Processor. 10.4 Color Display. 32 MB RAM (Expandable). Flash Drive. Teac Floppy Drive. Ethernet (RJ45). RS-232 Port. PS/2 Keyboard & Mouse Ports. Feedrate & Rapid Override. 280 in-oz Torque Servo Motors. Software. Windows Operating System. Conversational Programming. Auto Geometry Engine. Cutter Compensation. Linear & Circular Interpolation. Canned Cycles. Pocketing (Circular, Rectangular, Irregular). Helix & Thread Milling. Tool Length Offset. Subroutines. Program Diagnostics. Trial Run Mode. Real-Time Graphics. CAD/CAM Interface. Network Access. Automatic File Backup. INCLUDED ACCESSORY. Power Drawbar. Machine is under power and available for inspection. We can assist with loading. Please contact with any questions or to schedule an inspection. We want you to be happy and we also want to help you in any way possible. We want to build relationships with our customers and the best way to do that is by providing quality products, honest representations, value, and service. Again, we want to thank you for your time and interest and we look forward to earning your business in the near future. Thank You for stopping by and please view our other items. FOR ALL OF YOUR AIR, TOOLING, AND MACHINING NEEDS.

Comments Off

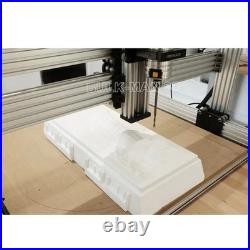

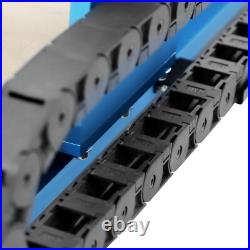

BULKMAN3D OXMAN CNC Router Machine Full Kit- 1610 Ball Screws for Wood Cutting. The OXMAN CNC Router is an industrial Grade CNC Newly designed with SFU16 (16mm) Ball Screws and Double Dual Extended HG&MGN Linear Rails trammission on each axis. All key components of the entire machine are installed with precision locaing pins, and all axes are protected by sheet metal and rein-forced aluminum. It is 100% fully self-developed, designed by BulkMan3D International R&D Team and copyrighted by BulkMan3D. The main difference between the 3 versions of OXMAN is the workbench, we recommend OXMAN ULTRA as it comes with complete deluxe workbench. This Full Kit Includes. 1500x1500mm OXMAN CNC Frame Kit (OXMAN or OXMAN PRO or OXMAN ULTRA for choice) (X axis and 2Y axis=SFS1610 Ball Screw, Z axis=SFU1204 Ball Screw) New Design Cable Drag Chain System 1x XYZ Probe (Free Gift) 1x Drill Bits (Free Gift) Wiring Shielded Cable Kit. Spindle Bundle Kit with Dust Cover-80mm – 2.2KW 220V Water-Cooled (Only with DDCS4 V4.1 OFF-LINE Control Box Option) – 2.2KW 110V/220V Water-Cooled Spindle Bundle (High Speed 7 Series 4 Bearings) – 2.2KW 110V/220V Air-Cooled Spindle Bundle (High Speed 7 Series 4 Bearings). Controller Bundle Kit with Stepper Motors – DDCSV4.1 OFF-LINE Control Box with 2.2N. M Closed Loop Stepper Motors – UC300 Mach3 with 2.2N. M Closed Loop Stepper Motors – DDCS4V3.1 OFF-LINE with 2.2N. M Closed Loop Stepper Motors. The Ball screw nut fixing and dismounting requires professional tools or done by professional stuffs! Never rotate the ball screw nut over the ball screw end! The OXMAN CNC excels at Cutting and 3D Carving through plastics, foam, softwood, hardwood and even soft metal such as aluminium and brass. Compatible Material for Cutting/Milling/Engraving : Aluminium / Hard Wood / Soft Wood / Oak / Plexi Glass / Delrin / HDPE / Foam and so on. Drill Bits & Milling Cutters. The OXMAN CNC can create intricate 3D carvings like wood artware, inlays, adverting logo, plaques, furniture, amazing art works and so much more. All the widely used applications can be achived here! DDCSV4.1 OFFLINE Control Box With 4pcs (57HSE2.2N) 2.2N. BulkMan 3DB-PRO DDCSV4.1 Industrial-gradeController Box is a high-performance control system specially designed to meet the needs of industrial manufacturing. Its rugged exterior and state-of-the-art technology ensure precise control of all CNC machine functions. The DDCS V4.1 is a standalone/offline controller, supports comprehensive Fanuc G code set file and can transfer the files by Ethernet communication between the computer and DDCS V4.1 controller, no size limited of the G-code file. The G-code design supports various software of CAD/CAM, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on. Meet the needs of various CNC machines: Engraving machines, Milling machines, Routers, Cutting. Etc. If you choose this controller bundle, the spindle options can only choose 1.5KW 220V water-cooled spindle bundle, and this spindle bundle does not include VFD. DDCS V4.1 4Axis Offline Control Box System with MPG Handwheel. This Control Box Includes. DDCS V4.1 4Axis Offline Control Box as Picture Shown. MPG Handwheel as Picture Shown. 4pcs (57HSE2.2N) 2.2N. Hardware Configuration inside this Control Box. 1x DDCSV4.1 Controller. 1x MC Power Supply S800-36V. 1x MC Power Supply LRS-75-24. 1x MC VFD 2.2KW/220V or 2.2KW/110V. 4x HBS57S Stepper Driver. 1x MC Plug-in Filter CW4L2-20A. 1x MC Wire-lead Filter CW1B-10A. 1x MC 4-channel relay-24V. 1x MC Fan 8025-24V. 2x MC Fan 6010-24V. 1x MC DB37 Terminal Block. Tips: Most Internal cables and modules inside this control box have been pre-connected, just follow our instruction to simply plug this box and it can work for your machine! DDCSV3.1 OFFLINE Controller Bundle With 4pcs (57HSE2.2N) 2.2N. This DDCS4 V3.1 Controller Bundle contains all the hardware for powering and controlling your OX-MAN CNC, Ultimate Bee, QueenBee Pro, WorkBee, Lead CNC, Ox CNC. Or other CNC machine. DDCS V3.1 numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation. The internal operating system is Linux based. The panel layout structure of the CR8-500 is very rational to save space. All operations are controlled by only 17 keys and a comprehensive G code set is supported. This controller bundle comes with 2.2N. UC300 Mach3 Controller Bundle With 4pcs (57HSE2.2N) 2.2N. This MACH3 Controller Bundle contains all the hardware for powering and controlling your OX-MAN CNC, Ultimate Bee, QueenBee Pro, WorkBee, Lead CNC, Ox CNC or other CNC machine. This UC300 system is an upgrade to our NVUM system. This Controller Bundle will allow you to use a Digital Dream UC300 Controller with a 4-axis machine CNC machine using MACH3 software. 2.2KW(110V/220V) Water Cooled Spindle Bundle. The 2.2KW Water Cooled Spindle is a heavy duty router, and due to the water cooled system, is comfortably capable of running for a long time without stopping, which makes it ideal for long, complicated jobs or applications. The VFD Inverter in this bundle are high quality from a well respected brand; Huanyang – an industry leader in CNC machining. It contains all the hardware for mounting a 2.2kW Water Cooled Spindle on a OX-MAN CNC, Ultimate Bee, QueenBee Pro, WorkBee, Lead CNC Machine or other CNC machine. 2.2KW Spindle Size: ø 80 x 238mm (Diameter: 80mm x Length: 238mm). Material: The cover is made of 304 stainless steel, and the water jack is high compression casting aluminium tube, red copper coil. Voltage: 2.2KW for 110V or 220V. AC Rated Current: 8 A. Max Rotation Speed: 24000 R/min. Water Cooled Run out: 0.01 mm. Bearing: 7005 bearings (3pcs), 7002 bearing (1pc). Coaxality: 0.025 mm (2.5 microns). Power interface: GX16 water proof aviation plug marked with numbers 1, 2, 3, 4. Numbers 1, 2 and 3 are connected to the inverter power U, V, W respectively. Number 4 is connected to the Earth wire Lubrication: High temperature resistance grease lubrication. 2.2KW Water Cooled Spindle Bundle comes with ER20 Collets from 1 mm to 13 mm. 28pcs:1mm/1.5mm/2mm/2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/7mm/7.5mm/8mm/8.5mm/9mm/9.5mm/10mm/10.5mm/11mm/11.5mm/12mm/ 12.5mm/12.7mm/13mm. 2.2KW (110V/220V) Air Cooled Spindle Bundle. The 2.2KW Air Cooled Spindle Kit is a very powerful Spindle we offer, which is a must have for anyone who takes their CNC machine serious. The VFD Inverter in this kit are high quality from a well respected brand; Huanyang – an industry leader in CNC machining. It contains all the hardware for mounting a 2.2KW Air Cooled Spindle on a OX-MAN CNC, Ultimate Bee, QueenBee Pro, WorkBee, Lead CNC Machine or other CNC machine. 2.2KW Spindle Size: ø 80 x 195mm (Diameter: 80mm x Length: 195mm). Material: The cover is made of 304 stainless steel. Power: 2.2 KW. Runout: less than 0.005 mm. Power interface: GX16 water proof aviation plug marked with numbers 1, 2, 3, 4 Numbers 1, 2 and 3 are connected to the inverter power U, V, W respectively. 2.2KW Water Cooled Spindle Bundle comes with ER20 Collets from 1 mm to 13mm 28pcs:1mm/1.5mm/2mm/2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/7mm/7.5mm/8mm/8.5mm/9mm/9.5mm/10mm/10.5mm/11mm/11.5mm/12mm/ 12.5mm/12.7mm/13mm. Terms of Sale (VAT). Return must include all original package and accesorries, item must in good condition. We will work with you to until you are satisfied. We will try our best to solve your problem to your satisfaction. We are always here with you! Our working time is 8 :30AM – 6:30PM from Monday – Friday.

Comments Off

High Z Mod for Lead CNC. The High Z modification for the LEAD CNC brings your creative capabilities to new heights! With 8? Of clearance this modification can be adapted easily to your existing LEAD CNC Router. The structural design is rigid and capable of milling through hard woods, plastics, foam. The sky is the limit with your LEAD CNC, its time to take your projects to the next level! This modification is for the LEAD CNC Machine. 8? Of clearance for Z-Axis. Additional X-Carriage and C-Beam for added strength. Adjustable mounting configuration for Z-Axis. Rigid modification design including additional framing components for added strength. When using an extended bit we recommend the use of softer materials, such as wood and foam. However, you can lower the Z axis down and cut harder materials just like the LEAD CNC. All our components are designed to work and are fully compatible with the products produced by OpenBuilds.

Comments Off

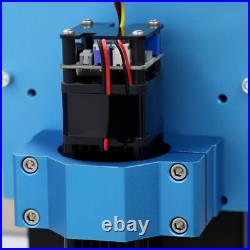

3 Axis CNC 6050 Milling Carving Engraver Router Machine Engraving Machine 500W. Our sophisticated engraving machine stands as a pinnacle of craftsmanship, poised to serve as an invaluable aide in your artistic endeavor of carving. With its precision-engineered design, it transforms mere materials into intricate masterpieces, elevating your woodworking craftsmanship to new heights. This elegantly crafted tool doesn’t merely shape wood-it breathes life into your vision, harmoniously fusing artistry with technology. Build to Last: It is composed of high-quality aluminum alloy with a sandblasting anodizing process, which makes it rust-resistant, sturdy, and has a long service life. Powerful Function: It uses a 57-76 stepper motor with a power of 500W and a speed of 10000rpm, which can efficiently and accurately carve according to your carving needs. Thoughtful Design: It adopts XYZ three-axis and easy-to-use integrated control box, with speed regulation, E-Stop, and Reset functions, which can better present your carving skills. In addition, it supports the Windows XP/7/8/10 system, making it easy for you to connect to a computer for precise engraving. Safety Protection: It has an air cooling design and an emergency stop switch, which can ensure timely heat dissipation, as well as the stability and use safety of the product during operation. Enjoy DIY: With it, you can do your own woodworking or plastic DIY to create your favorite works and enjoy the creative process! Ideal Gift: Because of its practicality and powerful functionality, you can give it as a Christmas, Thanksgiving, or Halloween gift to your worker friends. Protective Package: We have used sponge wrapping to minimize damage to the product during transportation. It is our pleasure to answer your confusion and questions. Sturdy Collet: You can mount the drill bit(not included) securely for engraving. Chain Design : The drag-chain cable design is not easily tangled and more beautiful and simple. It is compatible with laser heads and trimmers. It applies to Windows XP / 7/8/10. It can be used in factories, woodworking, workshops, advertising shops, etc. It is suitable for carving wood, aluminum, brass, organic glass, PCB, MDF, acrylic, resin, nylon, carbon fiber, PVC, etc. Color: Blue and Black. Plug Type: US Standard. Maximum Feeding Height: 115mm/4.53in. Y-axis Travel: 600mm/23.62in. X-axis Travel: 500mm/19.69in. Z-axis Travel: 120mm/4.72in. Y-axis Transmission: 1605 Roller Screw/15 Square Rail+Slider. X-axis Transmission: 1605 Roller Screw/15 Square Rail+Slider. Z-axis Transmission: 1204 Roller Screw/15 Square Rail+Slider. Z-axis Drive Motor: 57-76 Stepper Motor. Y-axis Maximum Operating Speed: 1500mm/59.06in/min. Z-axis Maximum Operating Speed: 1200mm/47.24in/min. Spindle Motor Power: Air-cooled 500W. Spindle Motor Speed: 10000RPM. Spindle Motor Collet Model: ER11. Spindle Motor Collet Camping Size: 1-7mm/0.039-0.276. Control System Data Transmission Method: USB. Machine Size: 88.877.355.5cm/34.9630.4321.85in. Workbench Size: 78.4 60.6cm/30.8723.86in. Package Size: 937316cm/36.6128.746.3inch. Gross Weight: 24.3kg/53.57lb. Net Weight: 24kg/52.91 lbs. YSB8SU-000200US(Frame and Machine). Package Size: 8349.524.5cm/49.519.499.65inch. Gross Weight: 24.6kg/54.23lb. Net Weight: 24kg/52.91lb. 1 Air-Cooled Spindle Motor. Other Accessories for Use. Please be patient as all parts arrive. Please allow the slight color difference caused by the shooting light and 1-3 cm error due to manual measurement, and make sure you do not mind before ordering. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. Easy installation, Compact Design. Router Engraver Milling Machine. Spindle Motor Collet Model. Spindle Motor Collet Camping Size. Control System Data Transmission Method.

Comments Off

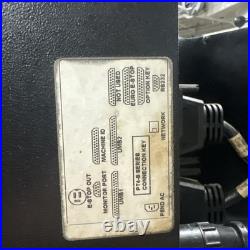

From a closing industrial facility. Untested but presumed to be working well.

Comments Off

USED END CAP DIAL BUCHINGS BEARINGS AND HANDLES. IF U NEED SCREWS WE ALSO HAVE SOME 32.36,42,48.

Comments Off

545mm Milling Machine R8 Spindle + Bearings Assembly. After the spindle is replaced, the old machine, such as the new machine effect, changes due to the long-term wear of the spindle, the bearing clearance is large, and the tool jumps, resulting in the surface and side of the milling workpiece is not smooth, rough and uneven. Name: Milling R8 spindle+bearings. Length:545mm(Suitable for most milling machines). Packing quantity: 1set(R8 spindle+bearings). You can make order with no worry. Any concern just feel free to let us know, we’ll reply in 24 hours in normal condition. Orders are processed from Monday-Friday. Not on the weekends & public holidays. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.

Comments Off

KEARNEY & TRECKER Arbor Support for Milling Machine 15 3271 – NICE. This is a good condition used tool. The item is in very good shape and is very clean. Does have cosmetic signs of use including worn paint, markings and blemishing. Nothing that impacts the integrity of the tool. Please see multiple pictures for more details. Thanks for considering this item. GENUINE TOOLS (About Us). Thank you for visiting our store. We are working to provide great condition new and used tools. If there is anything you are unsatisfied with please let us know and we will work to make it right. Your satisfaction and continued business is our top priority. We love great communication. Please let us know if there is anything we can do to satisfy you as a customer. You are our priority. AT and Marci Arneson. PLEASE CAREFULLY REVIEW OUR POLICIES BELOW. IF WE DO MAKE A MISTAKE, PLEASE LET US KNOW AND WE WILL DO WHATEVER WE CAN TO FIX IT. T LEAVE NEGATIVE OR NEUTRAL FEEDBACK UNTIL YOU GIVE US A CHANCE TO MAKE IT RIGHT. GENU Sales RESERVES THE RIGHT TO END ANY LISTING AT ANYTIME AND UPDATE OR CHANGE THESE POLICIES WITHOUT NOTICE.

Comments Off