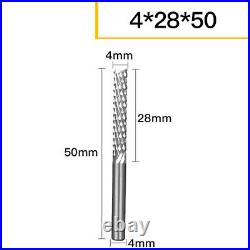

Flute End Mill Set, 20 Pcs. End Mill Set, High Speed Steel, TiN, 20, Fractional Inch. These sets include multiple high-speed steel square end mills in various sizes. Square end mills have a square nose and are rotated against a piece of stock to create flat-bottomed grooves with 9 Degrees inside corners. They are used for counterboring, side and face milling, and milling square shoulders. High-speed steel square end mills offer good wear resistance for basic milling applications. They’re more flexible and can absorb more shock and vibration than carbide end mills. Grainger Part #:16N204. Add to Favorite Sellers. Sign up to Newsletter. View more great items. THOMAS 617CA32 Piston Air Compressor, 0.125 hp, 1 Phase. CHAPIN 6-8153 Discharge O Ring Kit. GRAINGER APPROVED 2JGN1 Barrel Bolt, 5/8L, 316SS, #6-32, PK5. 3M 4930 Double Sided VHB Foam Tape, 5 yd L, 1/2 W. These items are intended to be used in North America. Power adapters and other modifications may be necessary for proper operation in other countries. GRAINGER STANDARD TERMS AND CONDITIONS. Please read these terms and conditions carefully. They contain important information concerning customer? Legal rights, warranties, obligations and available dispute resolutions remedies. They also provide that if Grainger is unable to resolve any matter to Customer? S satisfaction, Customer will exclusively use arbitration to decide the dispute and Customer will bring its claim solely on an individual basis and not in a class action or representative proceeding. Grainger reserves the right to revise these Terms and Conditions at any time. Product Compliance and Suitability. Jurisdictions have varying laws, codes and regulations governing construction, installation, and/or use of products for a particular purpose. Certain products may not be available for sale in all areas. Grainger does not guarantee compliance or suitability of the products it sells with any laws, codes or regulations, nor does Grainger accept responsibility for construction, installation and/or use of a product. It is Customer’s responsibility to review the product application and all applicable laws, codes and regulations for each relevant jurisdiction to be sure that the construction, installation, and/or use involving the products are compliant. S acceptance of any order is subject to Customer? S assent to all of the terms and conditions set forth herein. Customer’s assent to these terms and conditions shall be presumed from Customer’s receipt of Grainger? S acknowledgment, or from Customer? S acceptance of all or any part of the products ordered. No additions or modifications of Grainger? S terms and conditions by Customer shall be binding upon Grainger, unless agreed to in writing by an authorized representative of Grainger. Grainger reserves the right to accept or reject any order. The terms and conditions in: (i) Grainger? S forms; (ii) acknowledgments; (iii) quotations; (iv) invoices; (v) web sites; (vi) catalogs; and (vii) extension of credit are incorporated herein by reference, and constitute the entire and exclusive agreement between Customer and Grainger. Business Customers hereby agree to indemnify and hold Grainger harmless against any breach of this representation. ADDITIONAL TERMS AND CONDITIONS RELATED TO EXPORT OF GRAINGER PRODUCTS. IN ADDITION TO THE STANDARD TERMS AND CONDITIONS IN SECTION I, EXPORT SALES OF GRAINGER PRODUCTS WILL BE GOVERNED BY THE FOLLOWING ADDITIONAL TERMS AND CONDITIONS RELATED TO EXPORT OF GRAINGER PRODUCTS? IN THE EVENT OF A CONFLICT BETWEEN GRAINGER? S STANDARD TERMS AND CONDITIONS IN SECTION I AND THE ADDITIONAL EXPORT TERMS IN SECTION III, THE ADDITIONAL TERMS IN SECTION III SHALL PREVAIL FOR EXPORT SALES OF GRAINGER PRODUCTS. Customer acknowledges that no order shall be deemed accepted unless and until it is verified and accepted by Grainger, or any of its U. Affiliates and divisions, at a continental U. Facility or at any of its websites. Customer further consents that submission of its order shall subject Customer to the jurisdiction of the federal courts of the U. And of the State where acceptance occurred in the U. Grainger is required to charge U. Export Controls and Related Regulations. Customer represents and warrants that it is not designated on, or associated with, any party designated on any of the U. Government restricted parties lists, including without limitation, the U. Commerce Department Bureau of Industry and Security? Denied Persons List; Entity List or Unverified List; the U. Treasury Department Office of Foreign Assets Control? Specially Designated Nationals and Blocked Persons List; or the U. State Department Directorate of Defense Trade Controls? Customer shall comply with all applicable U. Economic sanctions and export control laws and regulations, including without limitation, the regulations administered by OFAC, the Export Administration Regulations? Administered by BIS, and the International Traffic in Arms Regulations administered by DDTC. It is specifically agreed that Customer shall be the foreign principal party in interest? In the event a license is required for export from the U. Agent of the FPPI the exporter of record for purposes of meeting EAR requirements. Country of Importation and Anti-diversion. Customer represents that it is purchasing products from the U. And importing them to the country for the use of the ultimate consignee specified in the Customer and Grainger documentation. Customer agrees that the products will not be resold, transferred, or otherwise disposed of, to any other country or to any person other than the authorized ultimate consignee or end-user(s), either in their original form or after being incorporated into other items, without first obtaining approval from the U. Government or as otherwise authorized by U. Any commodities, technology and software will be exported from the U. In accordance with the U. Export Administration Regulations and other applicable laws or regulations. Diversion contrary to U. Customer further agrees to inform Grainger at the time of order of any North American Free Trade Agreement or other special documentation, packaging or product marking or labeling, but Grainger shall not be responsible for providing any such documentation, packaging, marking or labeling other than such documents that are necessary under U. Export laws and regulations for export, unless Grainger expressly agrees to do so. Permits, Export, and Import Licenses. Customer shall be responsible for obtaining any licenses or other official authorizations that may be required by the country of importation. When the Customer is designated as the U. Principal Party of Interest, the Customer shall be responsible for obtaining licenses under the EAR, International Traffic in Arms Regulations, Toxic Substances Control Act, or other applicable laws or regulations. If the Customer is the FPPI, then the terms contained in subsection 6 of this Section III shall apply. The rights and obligations of the parties under these terms and conditions shall not be governed by the provisions of the 1980 United Nations Convention of Contracts for the International Sale of Goods or the United Nations Convention on the Limitation Period in the International Sale of Goods. Rather, these terms and conditions shall be governed by the laws of the State of Illinois, U. Including its provisions of the Uniform Commercial Code, but excluding its conflict of law rules.