2026

Look See Proxxon Ff 230 Micro MILL Accessories

Comments Off

Large CNC Mill – X axis Assembly. Length – Overall – 38.5. With – (linear slide) 4.5. Linear slide travel distance – 25- clear. Working plate – 14″x14″x. Motor – Nema 23. This aseembly can be all you can wish for an X axis assembly. THERE ARE MARKS ON THE WORKING PLATE – did not bother us but if you wish they can be eliminated with one pass of fly cutter. MOST OF THEM ARE LESS THAN 1/16 DEEP. An extra cleaning of the entire assembly is needed also. Linear slisde – Intelligent Actuator – MADE IN JAPAN. Working plate – Made in USA. NEMA 23 MOTOR – Unknown fabricator/. Specific requirements for this sale. Then please remember – the sale cannot be cancelled. This is the criteria of accptace.

Comments Off

Brand New Spline Gear Hub. For milling machine Step Pulley J Style Heads. Suit for Most Milling Machine. Please note size when yuou submit a order. Suit for 3# 4#Milling Machine. Package:1 Upper Spindle Gear. 1 Lower Spindle Gear. We provide 90 days return service, any question please contact me. We will do our best for your satisfaction. Therefore, please ask questions about products before you order it. It would also help you on your decision. On China holidays, replies for message may be delayed. (Please refer to notice on product description page or our information message). Before you open a case. We will definitely take care of your issue. Real time reply could be impossible due to the time difference. International Buyers – Please Note.

Comments Off

Lot of eleven assorted quill feed handles and components for milling machine assembly. See photos for all units included. From a closing industrial facility. The following information is provided by an AI description service. The product is a lot of 11 assorted mill milling machine assembly quill feed handles and components. These components are designed for milling machines, specifically for the function of milling. The lot includes various handles and parts to help with the operation and maintenance of milling machines in a manufacturing or industrial setting. These components are essential for ensuring precise and efficient milling processes.

Comments Off

HRC65 Solid Carbide Three Teeth Thread Milling Cutter M1 M1.2 M2 M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M24 M30 Balzers Coated End mill For Stainless Steel, Steeel, Titanium, Cast Iron.

Comments Off

Suit for most Turret and vertical milling machine. After the spindle is replaced, the work effect is as new. Package:1 Set NT30 Spindle+Bearing. We will respond to you very promptly.

Comments Off

Arbor Hole Diameter: 0.7500. Overall Height: 1.7500. Insert Compatibility: OFHT 040305SN. Maximum Depth of Cut: 0.0980. Number of Cutter Inserts: 7. Number of Flutes: 7. This listing is for One Face Mill that is in the picture as well as described. Tina December 02 2020. Rack Paco Shelf 1.

Comments Off

R1-R15 HSS Corner Rounding End Mill Radius Milling Cutter CNC Router Bits Knife. The Mill Cutter is usually assembled on milling machine. Suitable for CNC data processing center, carved and high-speed machines. Can mill copper, aluminum, tool steel, cast iron, etc. High toughness, abrasion resistance, and high-speed cutting for the high hardness. Can directly processing or fine processing to the heat treatment mold. Reduce the frequency of tool changes, improve machine actuator movement rhythm, save mold making time. Type: Corner Rounding End Mill. Material: High Speed Steel. Application: Used for milling low-carbon steel, aluminum, copper, iron and non ferrous materials. If you need more. Contacting me to get discounts. Package Include: According to your choose. All products in our store are elaborately made. We care about our valued buyers, if you have any questions, our Customer Service staff will be very glad to help you. We try our best to reply to your emails as soon as possible, however, due to the high volume of daily incoming emails and time zone difference, we may not be able to reply to your emails immediately. Please contact me before you return it. Feedback is very important to us. For the functional products in our shop, we make sure that the functions are the same as the description. About the product colour:Because of the different light and environment when the product is photographed, In a few instances the colour of the product may have a little colour difference with the actual colour of the product, I hope you can understand.

Comments Off

Shars 4 45° Indexable Face Mill ONHU 16 Cutting Edge Insert + Certificate. Indexable face mill, end mill. Axial Depth of Cut AP. Suitable for most face milling applications on steel, stainless steel, and cast iron. Reduces vibration on long overhang applications. Octagonal double side insert with 16 cutting edges is the most economical insert on the market for face machining application. Negative radial rake angle and axial rake angle structure combined with thick ONHU insert body improves cutter overall resistance to impact and toughness. Unique insert screw hole design to improve clamping rigidness. Insert available for semi-finishing and roughing application. Easy reference guide for insert number, screw, and other accessories is printed on the tool. CAT40 1-1/2″ x 4″ Face Shell Mill Tool Holder. ONHU 08T624R-GM YBG205 Carbide Insert. R8 1-1/2 Face Shell Mill Tool Holder. We also have different Face Mill and End Mill available, please visit my.

Comments Off

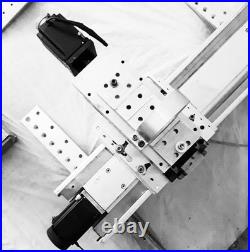

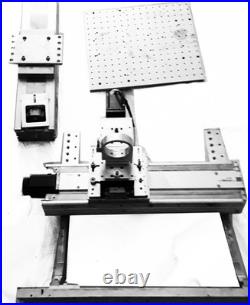

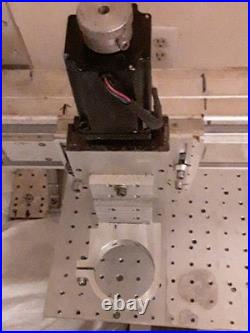

CNC MICRO MILL – Work in progress 90 percent ready. This machine represent the work of a professional lab next door. Their work was interrupted due to a terrible accident. This machine is almost ready what is missing is only a stepper motor and need some work to connect the main parts. X axis (the upper slide) – approx. Y axis – approx. The upper ring carrying the spindle is able to host a 65mm diameter CNC Spindle(not included). Z axis – 4 travel. WORKING HEIGHT CAPABILITY – This machine due to a pair of plates has the vertical extension capability up to more than 22 inch from the level of working plate – Very rare and expensive feature. Note about the extension capabilities. X axis cannot be easy extended due to the mill geometry. Y axis can be relative easy extended just replacing the y slide with a longer one and replacing the working plate also with a longer one. Observation: The working plate and Y axis need to be bolted in their place. Also machine will need its electronic command which is not included. Accounting – The initial price of all materials and parts was TWO – THREE TIMES BIGGER THAN OUR ASKING PRICE. All this assembly exceed 100 pounds and was too expensive to send it by track. The item is for sale AS WAS SHOWN.

Comments Off