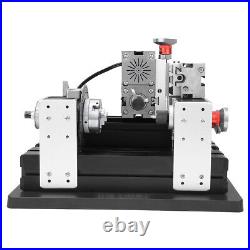

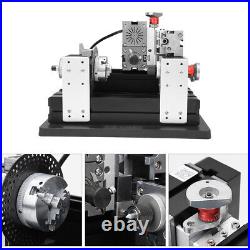

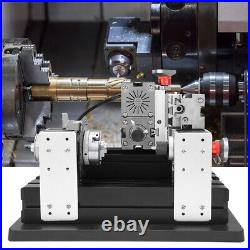

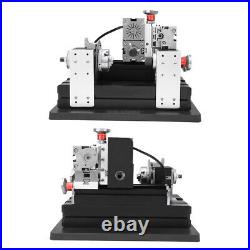

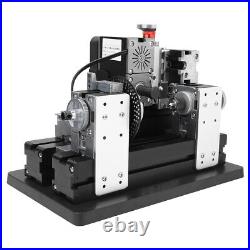

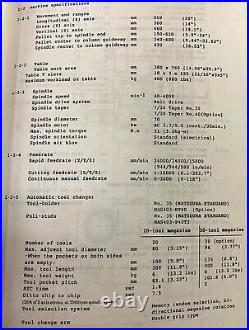

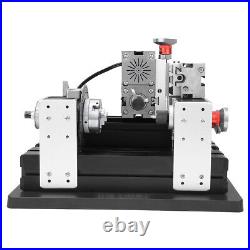

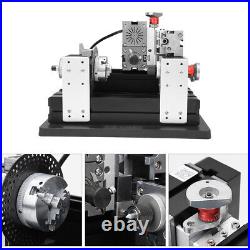

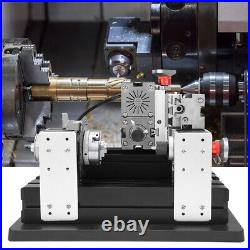

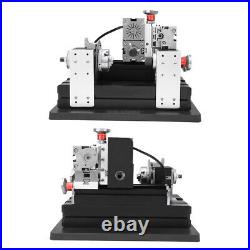

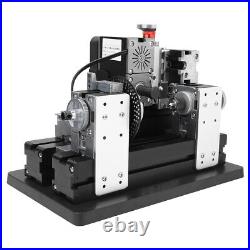

The motor casing and headstock are connected, using a more powerful motor, the maximum motor power is 144W, which can process gear 2. Use the spacer to drill round workpieces evenly 3. There are three round holes on the divider. Each round hole has the same ratio of holes. The number of holes on each circle is 36, 40, 48. We can choose them according to our needs. Three-jaw chuck with a maximum working material diameter is 50mm 5. Transformer has over-current protection, over-voltage protection and over-heat protection function. Item Type: Metal Milling Machine. Motor Speed: 12000rpm / min Input Voltage / Current / Power: 12VDC / 5A / 60W Working Materials: Wood, engineering plastics, soft metals gold, silver, copper, aluminum, etc. Maximum Working Material Diameter for Three-jaw Chuck Clamping: 50mm Transformer with over-current protection, over-voltage protection, over-heat protection The hand wheel has a 0.02mm graduation line, which improves the accuracy during processing Motor Power: 144W Module: 0.5, Accuracy: 0.03-0.05mm, Formula: Diameter D = module 0.5 x number of teeth + 1 Center Height: 50mm Z-shaft Travel: 32mm, Y / X-shaft Travel: 145mm Working Materials: Wood, plastic, acrylic, soft metal gold, silver, copper, aluminum, etc. 1 x Metal Milling Machine. 1 x Base Plate. 1 x Power Cable. 1 Bag of Accessories. Our listing price includes the value of goods, packaging cost, and export. Please check with your country’s. We will reply your message within 48 hours. If you do not receive our reply within 48 hours, pls. Post a message again because sometimes our message system may block some emails. If you are satisfied with our service, pls. Our aim is to provide Level Customer Service, your recognition will encourage us greatly and serve you better. We strive to keep all our customers satisfy. We will do our up most to exceed your expectations in customer service, communication and dispatching of your orders.