2024

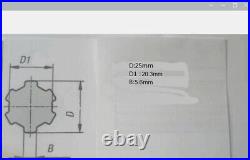

NEW 1 SET BRIDGEPORT Milling Machine Parts R8 Spindle + Bearings Assembly Kit

Cs-head{overflow:hidden;position:relative}. Title{margin:0;font-weight:400;font-size:14px;padding:5px 10px}. Dc-dock:hover{width:117px;background-position:bottom right}. Dc-cs{clear:both;max-width:100vw}. Dock-rb{right:0;bottom:0}. Title{font-weight: 400;font-size: 16px}. Title:after{content:’You may like’;color: #FFFFFF}. Cs-list>li:nth-child(n+7){display:none}. Title{margin:0;font-weight: 400;font-size: 16px}. Coupon{transform-origin:right top;right:0}. Cs-list{margin:0 0 0 -20px;padding:0;background:#FFF}. Cs-list:before{display:table;line-height:0;content:}. Cs-list:after{clear:both}. Cs-list>li{float:left;width:16.66%;list-style:none;box-sizing:border-box;padding:10px 0 10px 20px;position:relative;margin:0}. Cs-list-col6>li{width:16.66%}. Cs-list-col7>li{width:14.28%;padding-left:18px}. Cs-list-col8>li{width:12.5%;padding-left:16px}. Cs-list-col9>li{width:11.11%;padding-left:15px}. Cs-list-col10>li{width:10%;padding-left:14px}. Cs-list-col11>li{width:9.09%;padding-left:12px}. Cs-list-col12>li{width:8.33%;padding-left:10px}. Cs-list>liwidth:33.33%! Cover:after{display:block;content:”;padding-top:100%;background-repeat:no-repeat;background-size:cover;background-position:center}. Cs-list a{text-decoration:none}. Title{color:#333;margin:5px 0}. Title:after{display:block;display:-webkit-box;-webkit-line-clamp:2;-webkit-box-orient:vertical;font-size:14px;line-height:1.4em;height:2.8em;overflow:hidden;white-space:normal;word-break:break-word;-webkit-hyphens:auto;-ms-hyphens:auto;hyphens:auto}. Plus{height:20px;overflow:hidden}. Price:after{content:”;font-size:14px}. Origin{margin-left:3px;font-size:12px;color:#AAA}. Origin:after{display:none;content:”;text-decoration:line-through}. Coupon{display:none;width:60px;height:60px;border-radius:50%;background:rgba(224,13,12.8);color:#FFF;position:absolute;top:10px;right:10px;text-align:center;padding-top:12px;box-sizing:border-box}. Coupon:before{content:”;font-size:20px}. Coupon:after{content:’Off’;font-size:12px;position:absolute;bottom:8px;right:12px}. Title{min-height:12px}p:empty+hr{display:none}hr+span. Dc_tracker_img{display:none}#ds_div>. Dc_tracker_img:last-of-type{display:block} [data-lid="256581340237"]. Title:after{content:’Milling Machine Knee Crank Handle Mill Part Swivel for Bridgeport Profession’}[data-lid="256581340237"]. Title:after{content:’0.07kg Milling Machine Clutch Handwheel Easy Operation Easy to Carry B113 New’}[data-lid="256583316057"]. Title:after{content:’M1187 Milling Machine Parts J Head Milling Machine RAM Adapter Bridge Port Type’}[data-lid="256581344901"]. Title:after{content:’7/16 Thread Milling Machine Part R8 Draw Bar Overall Drawbar For Bridgeport Mill’}[data-lid="256581345925"]. Title:after{content:’Bridgeport Milling Machine C86+88 For X/Y Axis Dial Ring Lock Nut CNC Mill Part’}[data-lid="256581346205"]. Title:after{content:’Three-stage Switch Forward Reverse 3 Phase Motor Milling Switch High-quality’}[data-lid="256581341609"]. Title:after{content:’92mm Milling Machine Parts Gear Hub ALSGS Servo Power Feed Model AL-310S’}[data-lid="256581342414"]. Title:after{content:’A49 Belt Pulley Bridgeport Milling Machine Vertical Mill Part Transmission Motor’}[data-lid="256583317225"]. Title:after{content:’For 04-10 Toyota Sienna Outside Sliding Left Or Right Universal Rear Door Handle’}[data-lid="256582223602"]. Coupon:before{content:’50%’} [data-lid="256581335739"]. Title:after{content:’Storage & Display Box Case Holds 50 PCGS NGC ANACS Certified Coin Holders Slabs’}[data-lid="256581335739"]. Title:after{content:’2\’\’ Irrigation Spray Gun Sprinkler Gun Large 360°Adjustable Impact Area Water’}[data-lid="256581415071"]. Title:after{content:’164FT Heavy Duty Commercial PVC Plastic Strip Curtain Freezer Door Room Strip US’}[data-lid="256581341097"]. Title:after{content:’Commercial High Pressure Steam Cleaner Machine Home High Pressure Cleaning Tool’}[data-lid="256583324222"]. Title:after{content:’2 pcs Sliding Barn Door Hardware Kit Modern Closet Bi-fold Door Hardware Kit’}[data-lid="256582223243"]. Title:aftercontent:’NEW 12\\.

Comments Off