2026

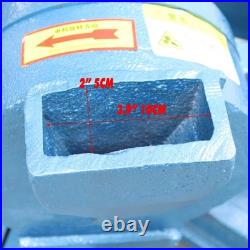

BF16 Precision Table Drilling and Milling Machine Cross Table 400 120\

Table size: 400 120MM. Index precision: 0.05MM.

Comments Off

Table size: 400 120MM. Index precision: 0.05MM.

Comments Off

ROEDER RFM600 PRECISION / HIGH SPEED VERT. ALWAYS SERVICED BY ROEDER. FISCHER 42K SPINDLE. HSK E40 TAPER. BLUM LASER TOOLSETTER. UPDATED SPINDLE CHILLER. X & Z BALL SCREWS REPLACED. X, Y, Z – 24″, 20″, 12. TABLE: 28″ X 20″. RMS 6 CONTROL.

Comments Off

Sturdy Feet:Non-slip feet effectively dampen vibration, preventing the machine from sliding while drilling for accurate drilling and milling. Protective Covers: Motor and belt covers can keep out dust and provide protection for longer product life. Limit Ring: You can use it to adjust the drilling depth limit. Sturdy and Durable: The premium aluminum, iron, plastic, and the oxidation process give the product excellent corrosion resistance and protect the product from abrasion and wear, ensuring a long service life. High Precision:Upper and lower double cover fixed design, three fixed spindles, fine adjustment screw, micrometer reserved holes, and scale to ensure the stability of the work, and attenuate the wobble, so that the work of higher precision. User-friendly Design:The fine adjustment screw and the utility handle allow you to operate the drilling depth with ease and high precision. In addition, the product is able to rotate 360° and move up and down as you wish, allowing you to drill and mill more flexibly. Wide Compatability: The multi-hole countertop is suitable for a variety of fixtures, making this product more expandable. Compact and Lightweight:With a compact size(4.725.910.6 in) and lightweight(4.85 lbs), the product is easy to move and simple to store without taking up much space when not in use. Easy to Clean:With a simple structure and smooth surface, you can easily wipe it clean with a soft cloth. It is our pleasure to answer your confusion and questions.

Comments Off

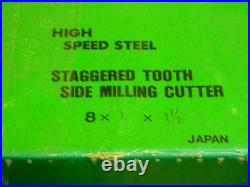

Cutting Diameter (Inch): 8. Cutting Width (Inch): 1. Cutting Width (Decimal Inch) :0.8750. Material: High Speed Steel. Arbor Hole Diameter (Inch): 1-1/2. Material Application: Ferrous Metals; Non-Ferrous Metals; Non-Metals. This listing is for One Side Milling Cutter that is in the picture as well as described. Tina January 08 2021. Cab A Bin 19.

Comments Off

Grinding Disc Crusher Grinding machine. The small disc mill crusher is a piece of high-efficiency equipment specifically designed for grinding and crushing ore materials. By means of its compact structure, flexible operation and stable performance, it is widely used in the scenarios such as laboratory sample preparation, small-scale mining processing and building material testing. It can precisely crush various kinds of ore (such as iron ore, limestone and granite) to meet material processing requirements with different fineness demands. Material of grinding disc: Manganese steel Voltage: 220V 50/60Hz 1PH Motor power: 1500W Driving mode: Belt driving (including a belt cover) Finished product collecting mode: Bottom collecting box Grinding fineness adjusting mode: Use the handwheels to adjust the gap between the grinding discs. Is integrally made of cast iron, stably supports the whole machine, ensures there is no obvious shake during operation and guarantees the grinding precision. Manganese steel grinding disc assembly. Comprises upper and lower manganese steel grinding discs rotating relatively, and is a core part for material crushing. The manganese steel material improves the grinding efficiency and wear resistance. Is composed of a 1.5KW 220V motor, belt pulley and driving belt. After the motor runs, the grinding discs are driven by the belt to rotate so as to grind the material. The belt cover is arranged outside the driving system to avoid the phenomenon that the belt is exposed to cause potential safety hazards. Is composed of an adjusting handwheel, adjusting screw rod and other components. The handwheel can be rotated to drive the screw rod to adjust the gap between the grinding discs, and then the material crushing fineness can be controlled. Is located on the top of the machine. The funnel design is adopted, facilitating material feeding. Meanwhile, the feeding speed can be controlled to avoid the phenomenon that due to too fast feeding, the machine is overloaded. Finished product collecting box. Is installed at the bottom of the machine and abuts against the discharging outlet below the grinding discs. The crushed material automatically falls into the collecting box. The collecting box adopts the pull-out or flip type design, so it is conveniently taken out and cleaned. Installation of collecting box. Operator requirements: Operators must be familiar with the contents of this manual and master the equipment operation methods and safety precautions before they can start working. Non-professionals are strictly prohibited from operating the equipment without authorization, and children are prohibited from touching and operating the machine. Power safety: The equipment must use the 220V single-phase AC power supply that meets the requirements, and the leakage protection device must be installed. It is strictly prohibited to operate the power switch with wet hands to avoid electric shock accidents. When the device is running, it is forbidden to plug or unplug the device. Protective measures: When the equipment operates, the belt cover must be installed in place, and it is strictly prohibited to start the equipment under the condition that the belt cover is not installed or is damaged. It is strictly prohibited to stretch hands or other objects into the feeding inlet, the gap between the grinding discs, and belt driving part to prevent the personal injury. During operation, wear a protective face mask to prevent splashing. Material safety: It is strictly prohibited to feed the too hard materials such as metal blocks and stones, or flammable, explosive or corrosive materials to avoid damaging the equipment or causing safety accidents. The material should be fed slowly and evenly to avoid material blockage in the feeding inlet. After the equipment is completely stopped, the fault should be checked and dealt with. The equipment must not be restarted before the fault is not solved. Equipment placement: The equipment should be placed on a flat and solid ground to avoid tilting and prevent the equipment from falling down during operation. The adequate space should be reserved around the equipment (it is recommended that the space should be no less than 0.5m) for convenient operation, maintenance and heat dissipation. Item included:Grinding Disc Crusher Grinding machine 1 Item Number: 134181. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.

Comments Off

Precision Milling Vise Vice Swivel & Angle Tilting 2 Way. ? REFURBISHED ITEM – FULLY TESTED & 100% WORKING?? Product: Milling Vice / Machine Vice. Use of Product: A milling vice, also known as a machine vice or mill vise, is a crucial tool used in machining operations to securely hold a workpiece in place while it is being worked on by a milling machine or other machine tools. It provides a stable, precise clamping mechanism that prevents any movement of the workpiece, ensuring accuracy and repeatability during milling, drilling, or other machining processes. The milling vice’s robust construction and adjustable jaws allow it to accommodate various sizes and shapes of workpieces, making it an essential accessory for achieving precise and consistent results in metalworking and manufacturing tasks. Versatile Design: Swiveling, tilting, and angling functions provide flexibility for a wide range of machining tasks. High-Quality Construction: Built from hardened steel or cast iron for strength and long-term durability. Swivel Base: 360° graduated swivel base with 1° increments for precise Y-axis positioning. Tilting Mechanism: Allows accurate machining at different angles while maintaining full stability. Angle Adjustment: Enables beveling, chamfering, and angular machining operations with ease. Secure Clamping: Robust clamping system ensures strong grip and prevents workpiece movement. Wide Jaw Opening: Accommodates both small and large components effectively. Smooth Operation: Precision-machined parts and ergonomic handles ensure effortless use. Durable Finish: Corrosion-resistant protective coating extends lifespan. Easy Installation: Comes with mounting hardware and instructions for quick setup. Professional-Grade Quality: Designed for machinists and hobbyists, offering accuracy, consistency, and superior performance. ? Perfect for milling, drilling, and complex machining tasks, this refurbished milling vice ensures professional results at an affordable price.

Comments Off

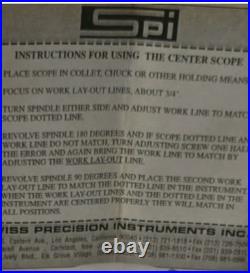

The Finn Swiss Precision Centering Microscope ISO 45X with Case Center Scope is a high-quality milling machine designed for precise metalworking. With its manual, CNC, semi-automatic, and automatic control options, this machining center offers versatility in various manufacturing processes. The included case provides convenient storage and protection for the microscope, ensuring that it remains in optimal condition for continuous use. The Finn Centerscope model is known for its reliability and efficiency, making it a valuable asset for businesses involved in metalworking and manufacturing.

Comments Off

Ohio Based Home Workshop Specialist. An ideal light weight, portable milling machine for home workshop, include all essential accessories like drill chuck, collet set, clamping kit, ready to go. The MD1009 series mini milling machine with L/R auto feeder can power through up to 3/8″ drilling, 1/4″ end mills, and 3/4 facing for the consistent results you need. This mini mill features L/R Auto Feeder, the highly stable Integrated ER16 Spindle that offers versatility, quick and easy tool changes and exceptional accuracy. The MD1009 series mill has variable speed up to 20000 RPM. The X axis (L/R) Auto Feeder can produce highly accurate and consistent parts, ensuring that each part meets the required specifications. Modify the spindle height with the rapid down feed or use the micro down feed to adjust down to 0.002″ (one full revolution is 0.07″). The MD1009 manual was written by our U. Based Documentation Department is packed with useful information. X axis (L/R) Auto Feeder. Integrated ER16 High Precision Spindle. 3/8″ drilling 1/4″ end mill 3/4 face mill capacity. Variable 20000 RPM Micro feed head control. End milling capacity: 1/4. Face milling capacity: 3/4. Motor: 1/4 HP, 110V, single-phase. Spindle Type: ER16 Integrated. Spindle speed: Variable Max 20000 RPM. Maximum distance spindle to table: 6.3. Maximum distance spindle to column: 4.5. Table size: 3.5″x11.8″. Table travel (longitudinal): 7.48. Table travel(cross): 2. Minium micro down feed: 0.002″ (0.07″/revolution). X axis auto feed rate: 0.34/min. Overall dimensions: 18″W x 14″D x 13H. 1 x Milling Machine. 6 x ER25 Collet: 3,4,5,6,8,10mm. 2 x Open end spanner: 5.5-7mm, 17-19mm. 6 x Allen key set: 2.5, 3, 4, 5, 6, 8mm. 1 x 3/8 Drill chuck with arbor (10mm Short straight). 4 x Clamping Kit (Block, T-nut, Stud, Hex nut, bolt). 1 x Oil bottle.

Comments Off

3/4 CAP NO 3 JACOBS 3/4 SHANK 0-17/32 CAP ALL 5/8 SHANK. ALBERCHT HAS 3/4 SHK LOOK TO BE IN EXCELLENT SHAPE SELL KEYLEES THROWNING IN T JACOBS BONUS.

Comments Off

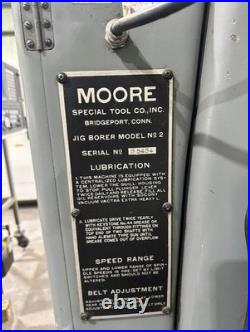

Moore Jig Borer Model No 2 Machine Precision Boring Press Mill 19″x10″.

Comments Off